Wooden Director Chair Wholesale

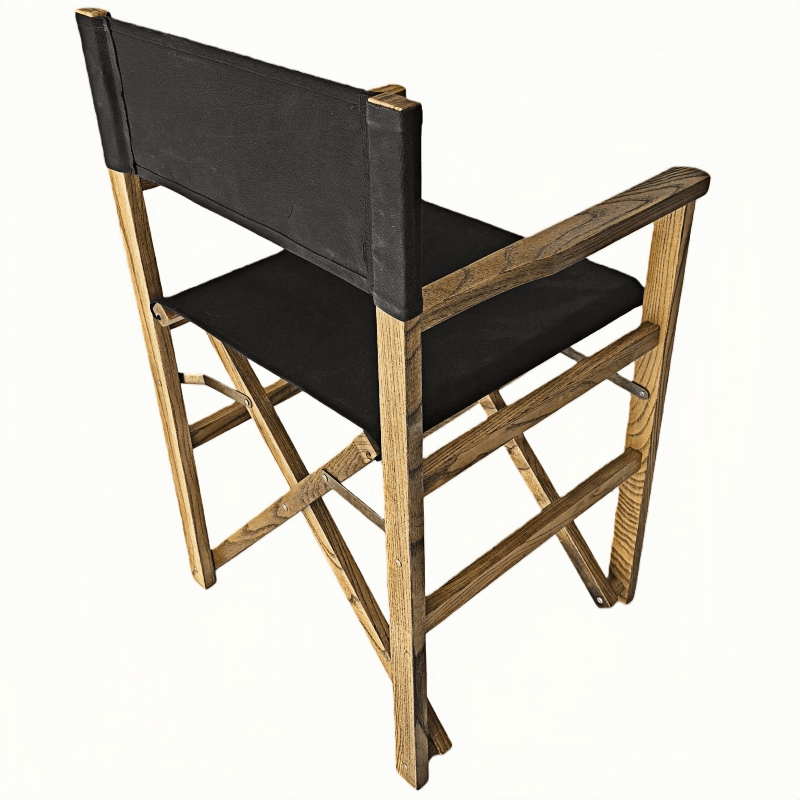

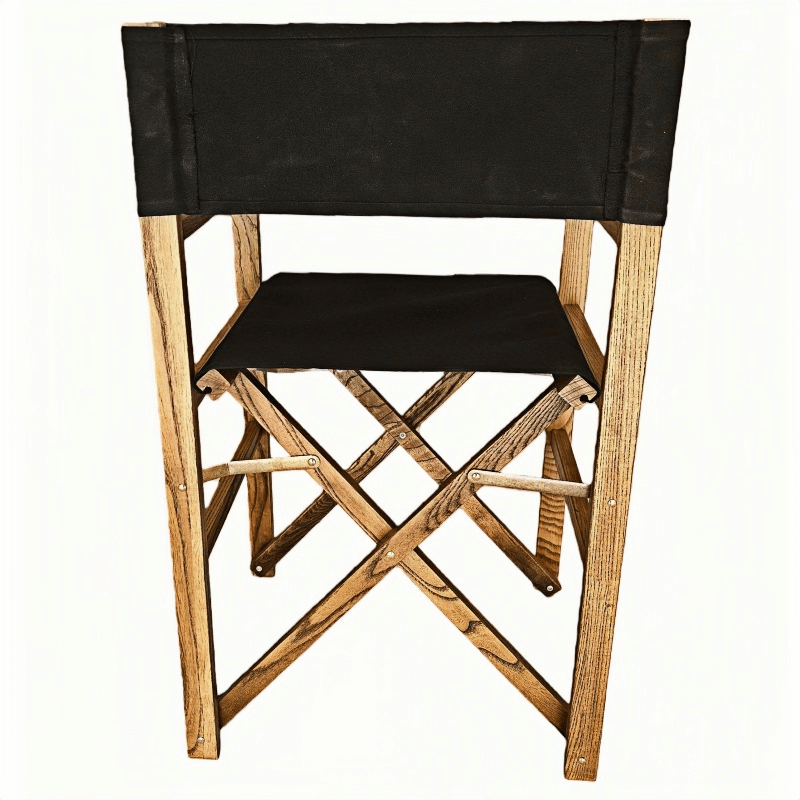

This classic wooden director’s chair features a solid wood frame, a durable canvas seat and backrest, and a simple, timeless design. Its foldable construction makes it easy to open and close, facilitating transport, storage, and on-site installation. The spacious canvas seat offers both comfort and stability, providing reliable support, while the wooden armrests add a touch of natural sophistication. This chair is ideal for event rentals, weddings, outdoor ceremonies, film sets, and other temporary seating arrangements that combine aesthetics and practicality.

Wooden Director Chair Feature

- It can be easily folded flat for convenient storage and transportation, making it an ideal choice for rental companies and large events. It can be easily folded flat for convenient storage and transportation, making it an ideal choice for rental companies and large events.

- Made of sturdy, solid wood with clearly visible grain, it provides reliable support and has a classic, high-end appearance.

- The sturdy canvas fabric provides a comfortable seating experience and maintains its shape even with repeated use.

- Suitable for weddings, outdoor events, film productions, exhibitions, and commercial rentals.

Description

The director’s chair measures 57 × 49 × 90 cm (width × depth × height). Its reasonable dimensions ensure stability

while facilitating easy placement, transport, and storage, making it suitable for various commercial and event scenarios.

Our director’s chairs are made of premium ash wood, featuring a sturdy and stable structure with a natural

and clear grain. They offer both strength and portability, making them suitable for frequent use and movement.

Standard colors include classic black and white, with a simple and versatile design suitable for various shooting

scenarios and event spaces. We also support custom color options to meet both bulk purchasing and

personalized customization needs.

How is a director’s chair transformed from raw material into a finished product?

Raw material selection and preparation

This wooden director’s chair is made of solid wood. We rigorously select natural solid wood, choosing only

pieces with stable density, uniform internal structure, and clear, natural grain. This ensures the chair maintains

excellent load-bearing capacity and structural stability even after long-term use and repeated folding.

Furthermore, to guarantee consistency in color, grain, and overall appearance for every chair in a bulk order,

we use standardized wood materials to meet the visual requirements of weddings, events, and rental projects.

Before processing, all wood undergoes appropriate drying and moisture content control to stabilize the wood.

This process effectively reduces the risks associated with fluctuations in internal moisture content, minimizing

the risk of deformation, cracking, or loosening due to environmental changes later on. This lays a solid foundation

for the durability and reliability of the director’s chair during long-term, high-frequency use.

Once the wood is prepared, workers use machines to cut each component, including the chair legs, armrests,

and cross braces, to ensure a precise fit during assembly. All wooden surfaces undergo multiple sanding processes

to create smooth edges and a comfortable feel while retaining the wood’s natural grain.

Hardware installation and folding structure assembly

The director’s chair’s hardware is made of thickened metal sheet through stamping, primarily used for the

folding connections between the chair legs and cross braces. The hardware surface is treated with rust

prevention, resulting in a uniform color and maintaining stable performance even under frequent opening

and closing and long-term use, preventing deformation or loosening.

Each connection point between the metal sheet and the director’s chair is secured with rivets, ensuring smooth

rotation and a natural feel during folding and unfolding, effectively guaranteeing the load-bearing capacity and

overall stability of the director’s chair during use. The metal edges undergo basic treatment to avoid burrs,

reducing safety hazards during installation and use.

After the wooden frame of the director’s chair is sanded, experienced workers assemble the hardware and

frame together, manually aligning each connection point to ensure smooth opening and closing and even

stress distribution during folding.

During assembly, workers use screws and connectors of uniform specifications to ensure structural consistency

across the entire batch of products. Workers repeatedly check the flexibility of rotation and the firmness of

connections during installation to prevent loosening or misalignment.

Overall assembly and functional inspection

The director’s chair features straight lines in its legs and armrests, and its folding mechanism opens and

closes smoothly, making it suitable for high-frequency use. During mass production, strict control is maintained

over dimensions and manufacturing processes to ensure that each director’s chair maintains a consistent

standard in terms of load-bearing capacity, stability, and appearance, meeting the bulk purchasing needs of

weddings, event rentals, and commercial projects.

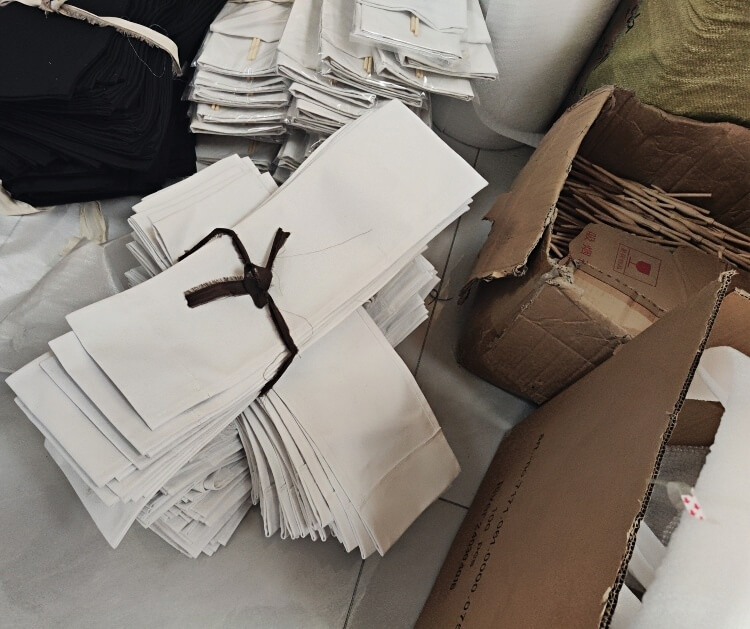

Fabric and support rod installation

Our director’s chair fabric accessories are designed as a set, including seat/backrest fabric and side mounting

rods, which are used to secure the fabric and attach it to the director’s chair frame.The mounting rods on both

sides are made of solid material with good straightness. The surface of the wooden rods is smooth and burr-free.

The size is perfectly matched with the reserved channel of the fabric, so the installation is smooth and not easy to loosen.

The director’s chair is made of durable and sturdy fabric, with precise cutting, strong stitching, and smooth

edge finishing, and can withstand frequent daily use and repeated disassembly and assembly.

During the production of the fabric and mounting rods, workers will check the dimensions of the fabric and

mounting rods separately to ensure that the entire set of accessories maintains stability and consistency

when used in batches, and can be easily and quickly replaced and maintained.

After the workers complete the quality inspection, the fabric accessories will be neatly folded and packaged

together with the corresponding number of installation sticks. The fabric is placed separately in a transparent

protective bag, and the installation sticks are placed inside the bag or secured separately to prevent damage

caused by friction during transportation.

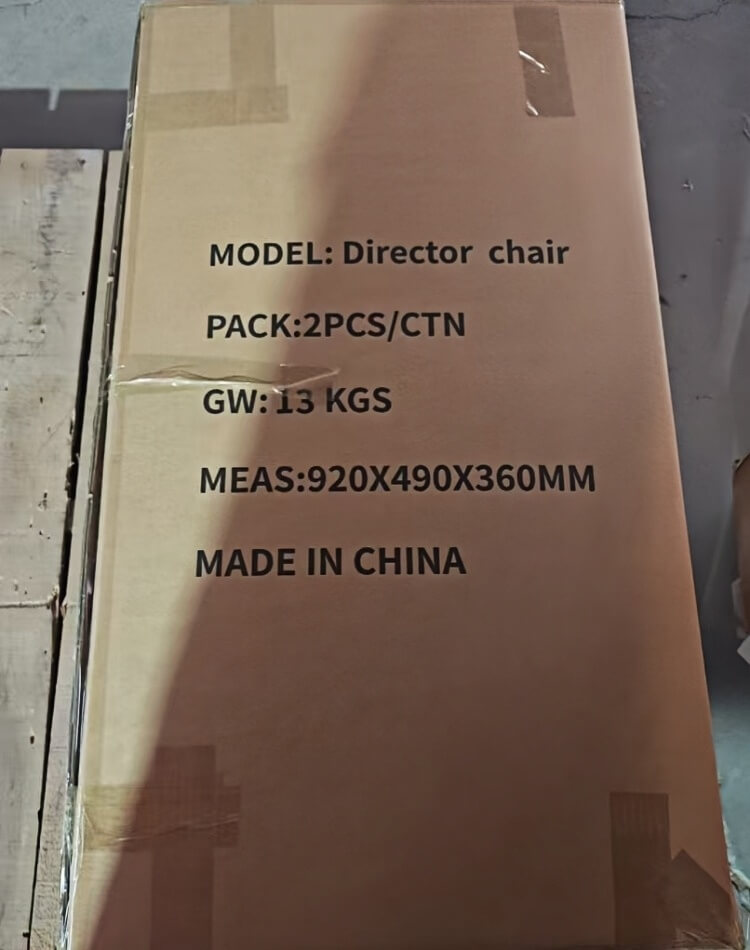

Packaging and Shipping Preparation

After passing factory inspection, each director’s chair is first completely wrapped in thickened bubble wrap,

providing all-around protection for the chair frame, armrests, backrest, and fabric parts, effectively cushioning

vibrations and impacts during transportation.

The wrapped chairs are then packed into sturdy, pressure-resistant cardboard boxes, custom-made to the

dimensions of the chairs to ensure internal stability and prevent wobbling. This double packaging effectively

prevents scratches, compression, and external impacts, enhancing safety during long-distance transportation

and bulk shipments.

This modern director’s chair adds extra seating to any space. Its sturdy hardwood frame features clean,

square lines, paired with a durable outdoor fabric seat. Whether in a dining room or on a patio, this classic chair

is a perfect fit and folds down for easy storage.

Reviews

There are no reviews yet.