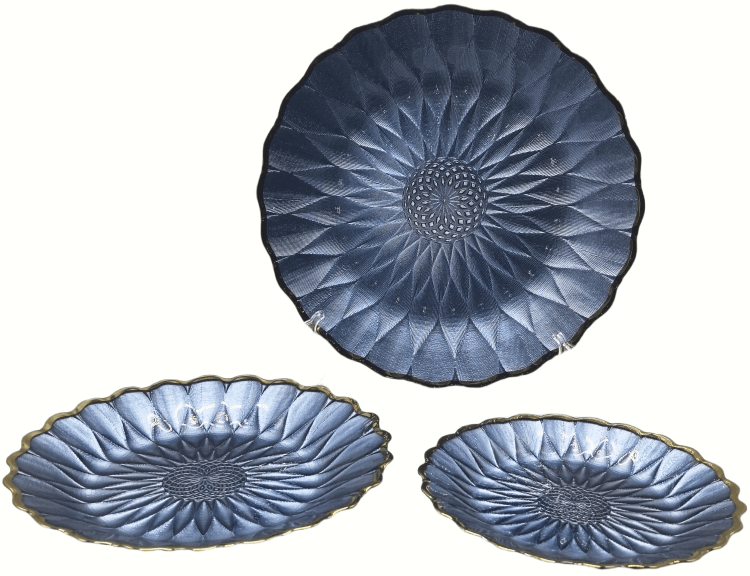

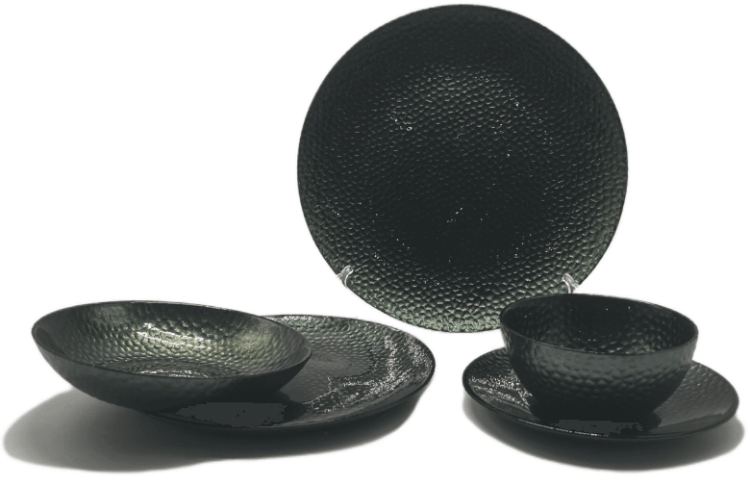

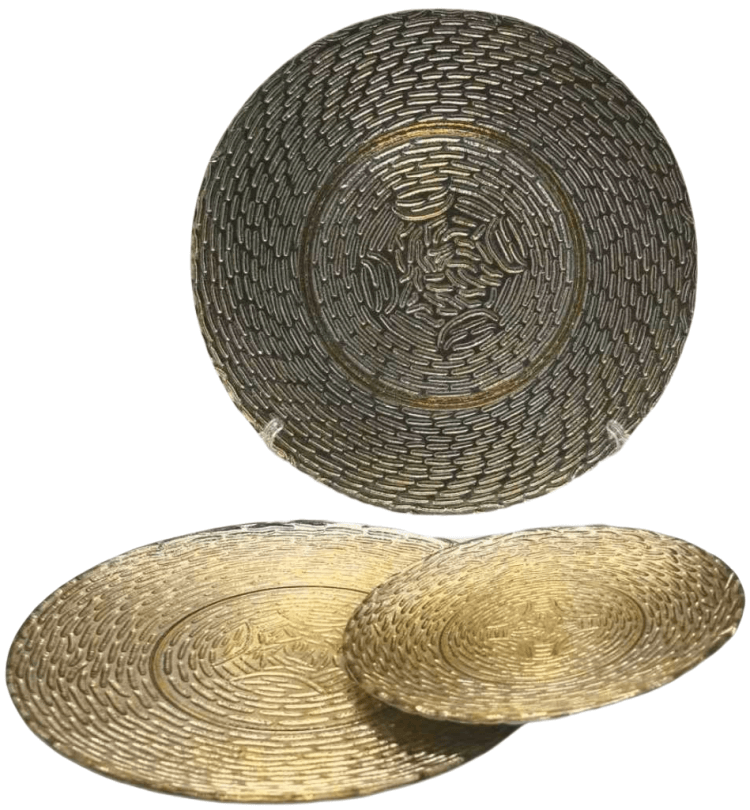

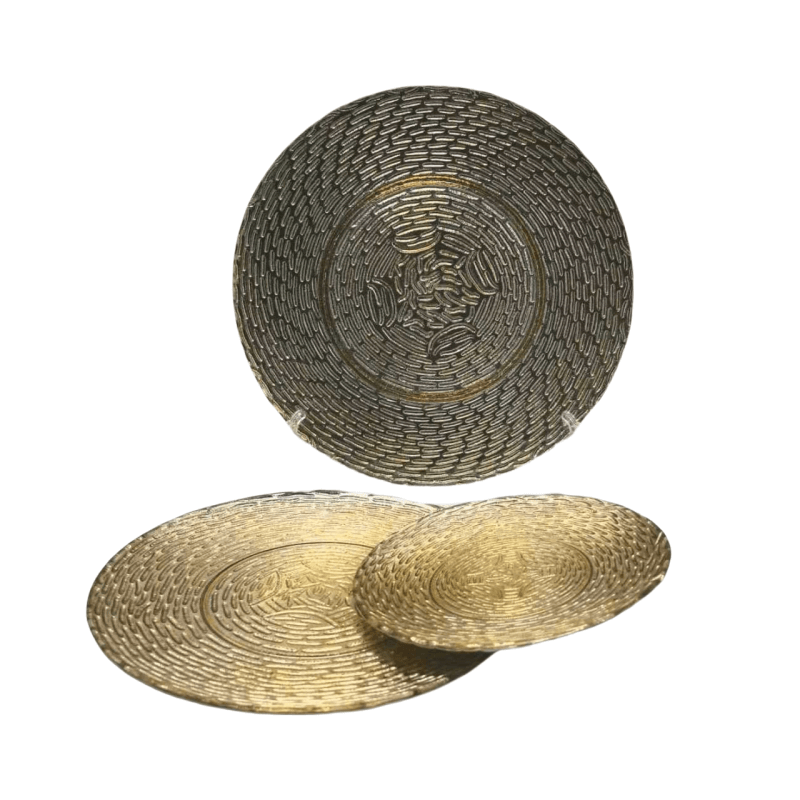

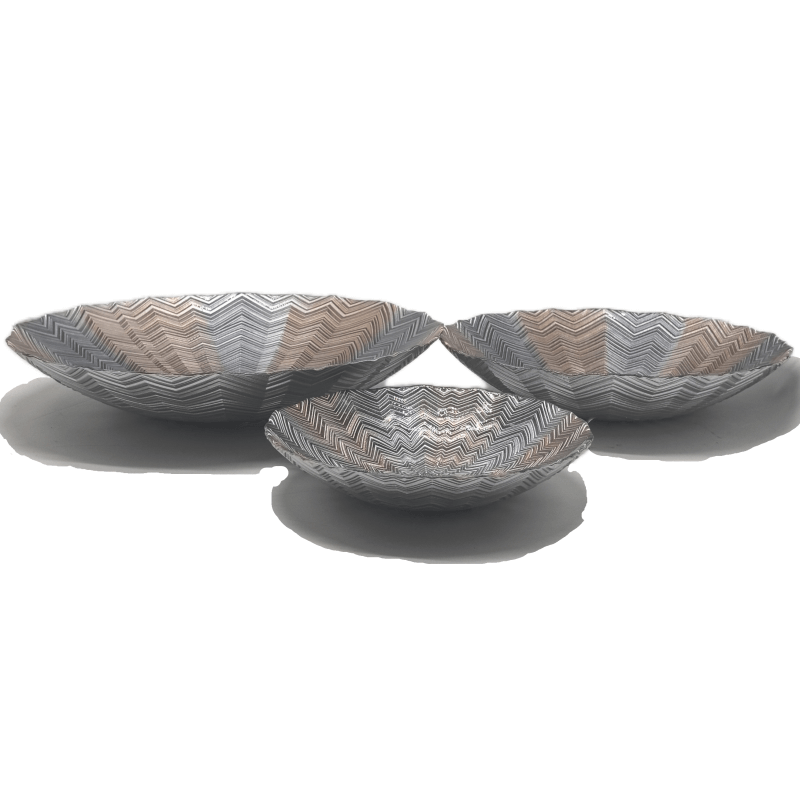

Glass Charger Plates Manufacturer

This glass charger plates is specially designed for weddings and banquets. Made from high-transparency glass, the plates are clear and transparent, with a pure and natural texture. Under the illumination of lights and complemented by floral arrangements and tablecloths, it effectively enhances the overall table setting and sense of occasion. The plates undergo molding and annealing processes, resulting in a stable structure that is not easily deformed, with smooth and delicate edges, making them both beautiful and safe. Whether used for wedding head tables, banquet settings, or buffet displays, it presents an elegant and sophisticated visual effect, making it an ideal choice for wedding decorations and banquet displays, combining both decorative and practical functions.

Glass Dinnerware Set Feature

- The wedding glass plates are crystal clear and transparent, reflecting a soft glow under the lighting, significantly enhancing the overall elegance of weddings and banquets.

- The rim of the banquet glass plate is delicate and smooth, and can be paired with decorative elements such as beaded or gold edges, highlighting the details and making the overall presentation more effective.

- It can be easily paired with tablecloths in white, champagne, black, and other colors, and is suitable for Chinese, Western, and modern weddings.

- Glass plates have a smooth surface, are easy to clean, and are suitable for repeated use in hotels, banquet halls, and by wedding companies.

Description

Glass Charger Plates Molten Glass Gathering

Workers place the glass raw materials into the furnace, where they completely melt at temperatures above

1400℃, becoming a bright orange-red fluid. Using specialized tools, the molten glass is precisely extracted,

preparing it for subsequent pressing and molding. This entire process demands extremely precise temperature

control and extensive operational experience, directly determining the transparency, uniform thickness,

and overall quality of the glass charger plates. It is one of the most critical core stages in the production of

high-quality banquet glass serving plates.

The high-temperature molten glass, taken from the furnace, is quickly transferred into custom-made metal

molds. While the glass is still in a malleable state, it is shaped through mechanical pressing or gravity molding

to form the fixed diameter, thickness, and edge profile of the glass tray.

Demonstration of the annealing process for glass dish sets.

The molded glass trays are neatly placed in an annealing furnace for slow, controlled cooling, which releases

internal stress and effectively prevents cracking or deformation later on.

The molded glass trays are neatly arranged in layers on a special metal rotating rack and then placed into

a large annealing furnace. Through a slow and uniform temperature control and cooling process, the internal

stress generated in the glass during high-temperature molding is fully released, effectively reducing the risk

of cracking, deformation, or spontaneous breakage later on. The multi-layered rotating structure not only

improves the efficiency of each batch but also ensures that every glass product undergoes annealing in a

stable environment, laying a solid foundation for subsequent grinding, polishing, and quality inspection.

Edge Polishing

After cooling, the glass plates undergo edge grinding and polishing. Through multiple stages of fine grinding

and polishing, any burrs and sharp edges are removed, resulting in a smoother, more rounded edge that is

safe to handle. This process not only effectively improves the safety of the product during handling and use

but also gives the glass plates a cleaner, more refined look with a uniform and delicate sheen, further

enhancing the product’s visual appeal and perceived quality. The polished glass plates are ideal for use in

wedding banquets, hotel and restaurant settings, and for wholesale applications.

Glass Charger Plates Surface Decoration

Workers are meticulously attaching crystal beads to the edges of the glass serving plates, using a manual

gluing method to ensure each bead is evenly spaced and precisely positioned. The transparent, lustrous

beads extend in a circle along the rim of the plate, creating a delicate and translucent sheen under the light,

making the overall design more refined and elegant. This process not only enhances the decorative effect of

the glass serving plates but also makes the finished product more visually appealing and sophisticated for

high-end events such as banquets and weddings.

How are glass charger plates packaged and loaded into containers?

During the packaging and container loading process, the glass plates are protected using a layered packaging

solution. Each plate is separated by pearl cotton or foam padding, with particular attention paid to protecting

the edges and decorative rims to prevent scratching or damage during transportation. The outer layer uses

thickened cardboard boxes or custom-made wooden crates for reinforcement, ensuring overall stability and

preventing movement. During container loading, the plates are arranged and stacked in a logical manner

according to size and weight, with the boxes neatly arranged and secured in place. This maximizes the use of

space within the container while effectively reducing transportation risks and ensuring the safe arrival of the

plates during long-distance and international shipping.

Wedding Plate Showroom

Our plate display area showcases a wide selection of high-quality tableware, each piece meticulously designed

and crafted to exhibit perfect craftsmanship and elegant texture. Whether for weddings, banquets, or everyday

dining, our plates will add a touch of unique sophistication and style to your dining experience. The smooth and

delicate surfaces and rounded, safe edges, combined with a thoughtful display arrangement, allow each plate to

fully showcase its beauty and practicality, enabling customers to easily appreciate the quality and style.

Reviews

There are no reviews yet.