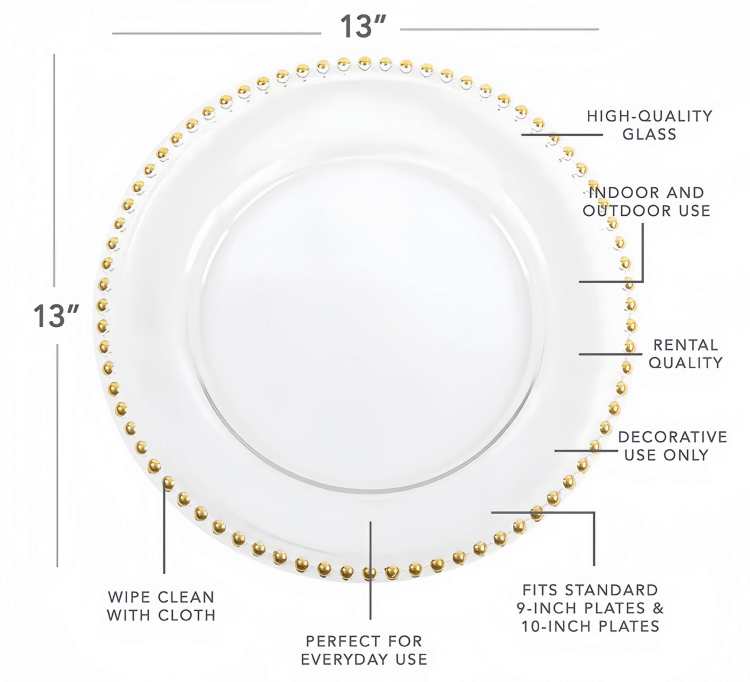

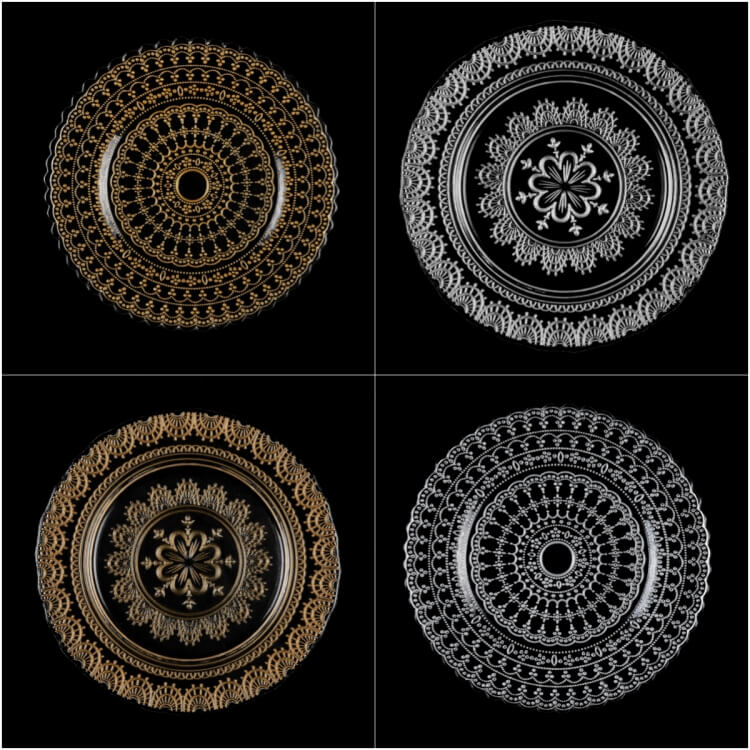

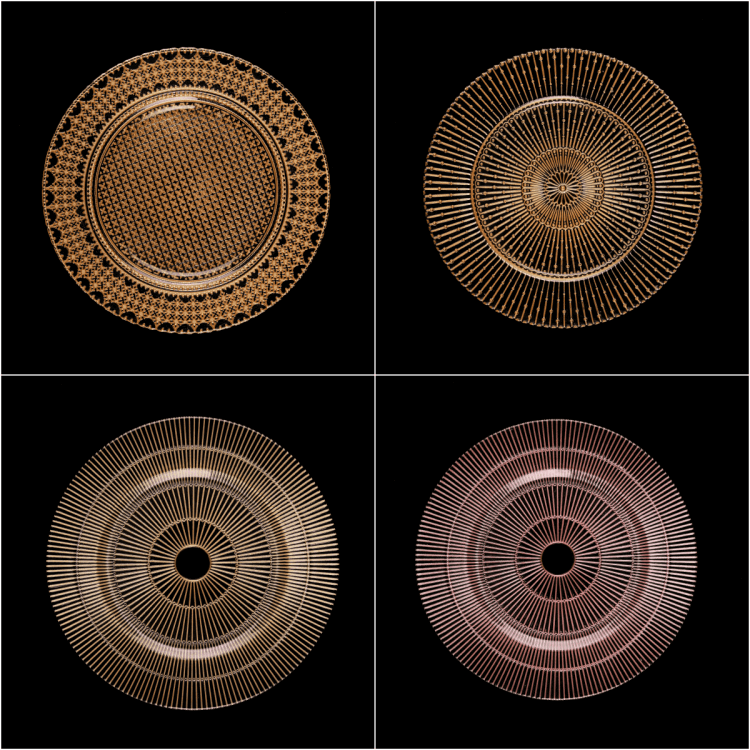

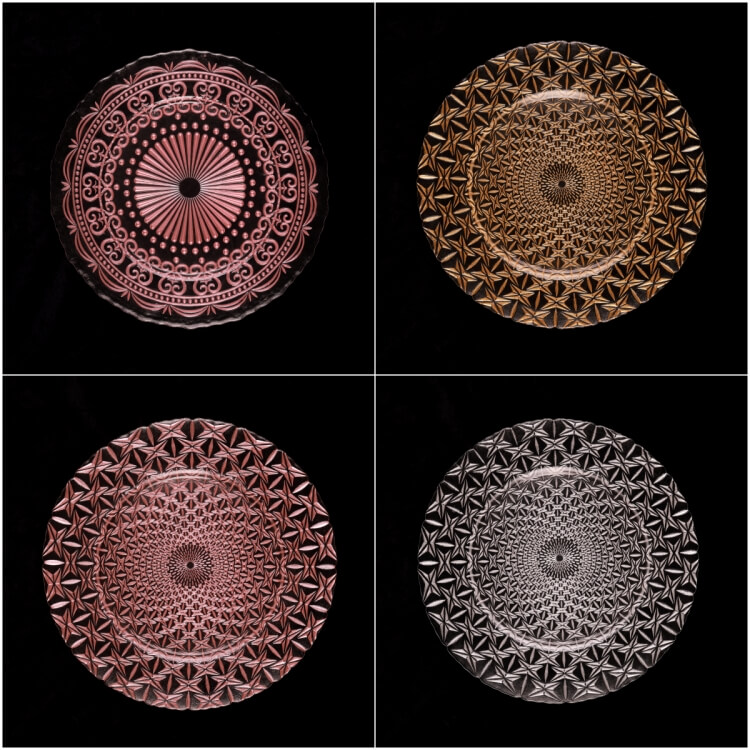

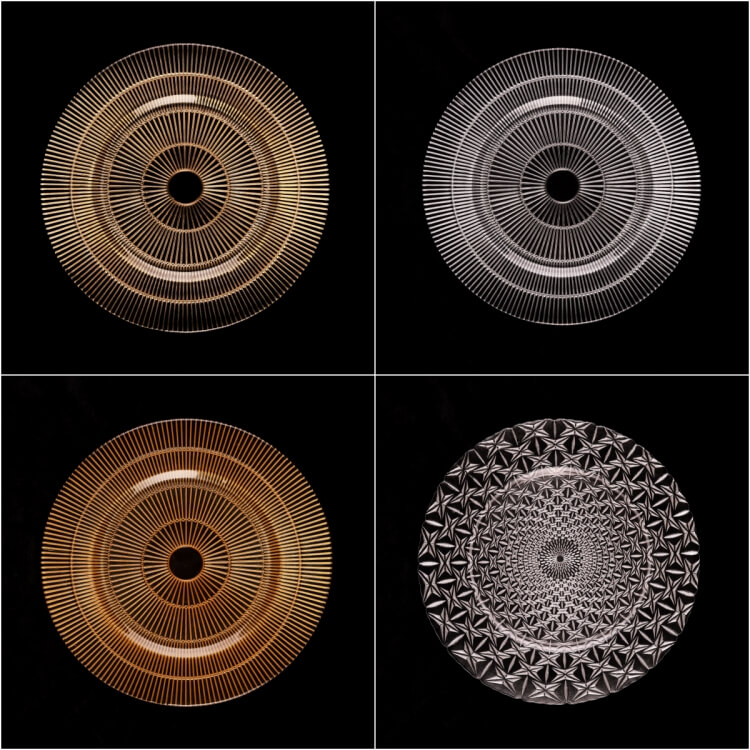

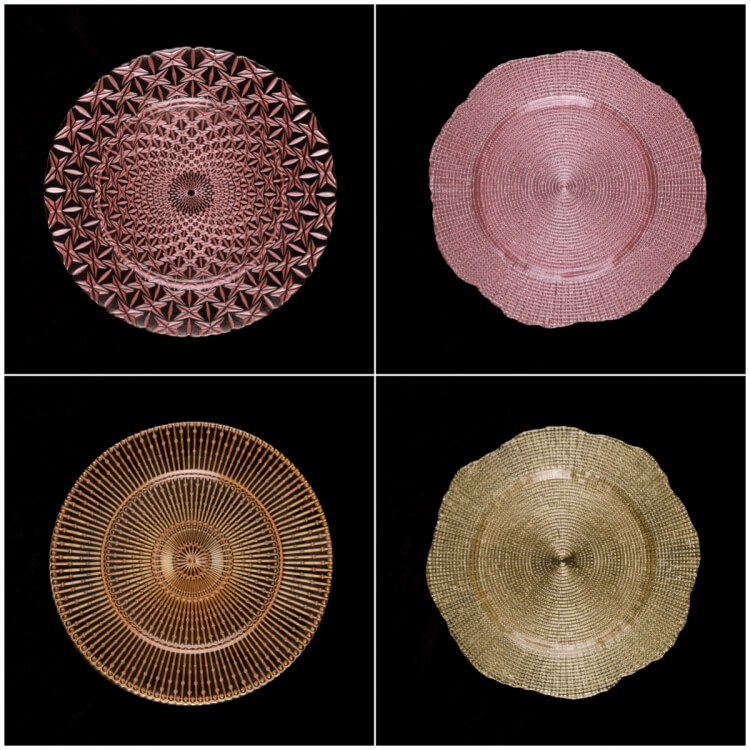

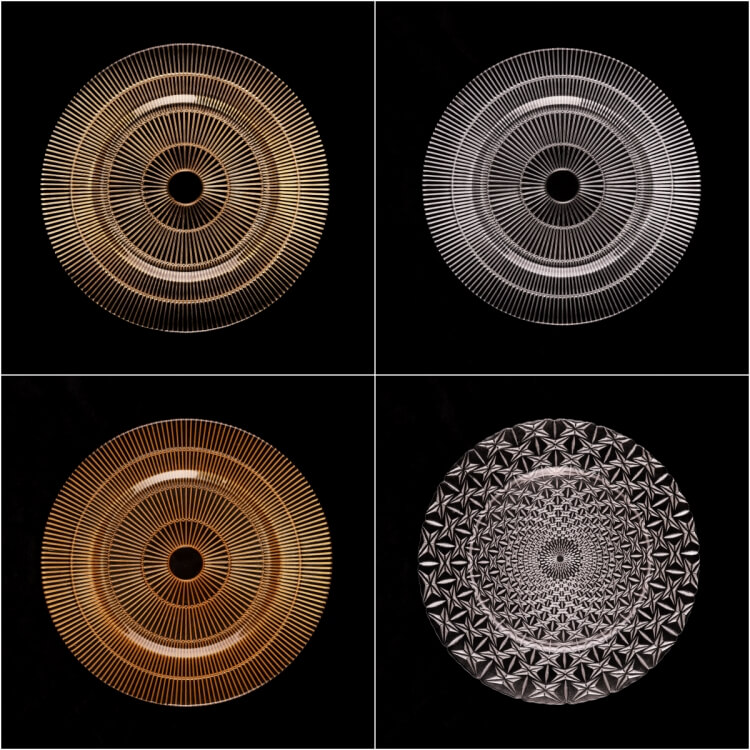

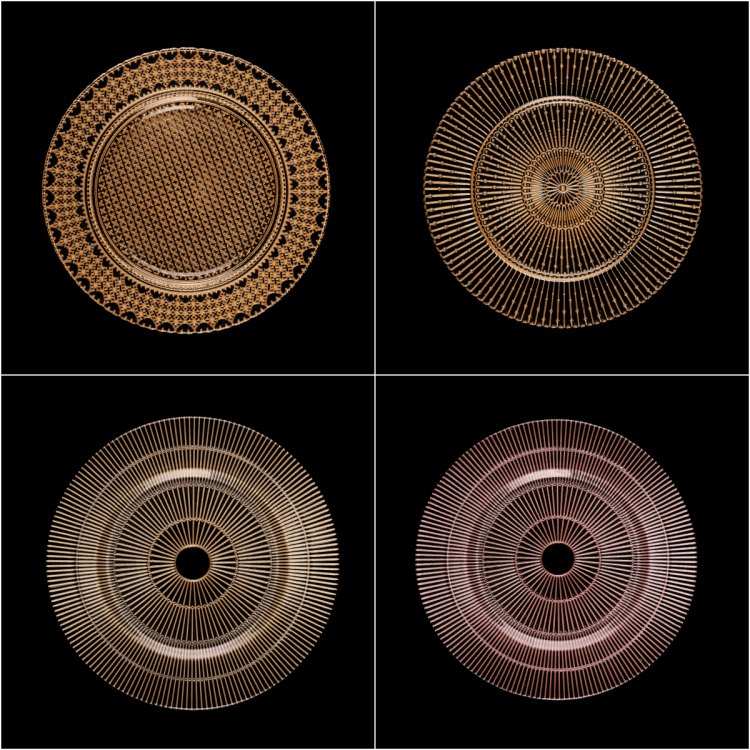

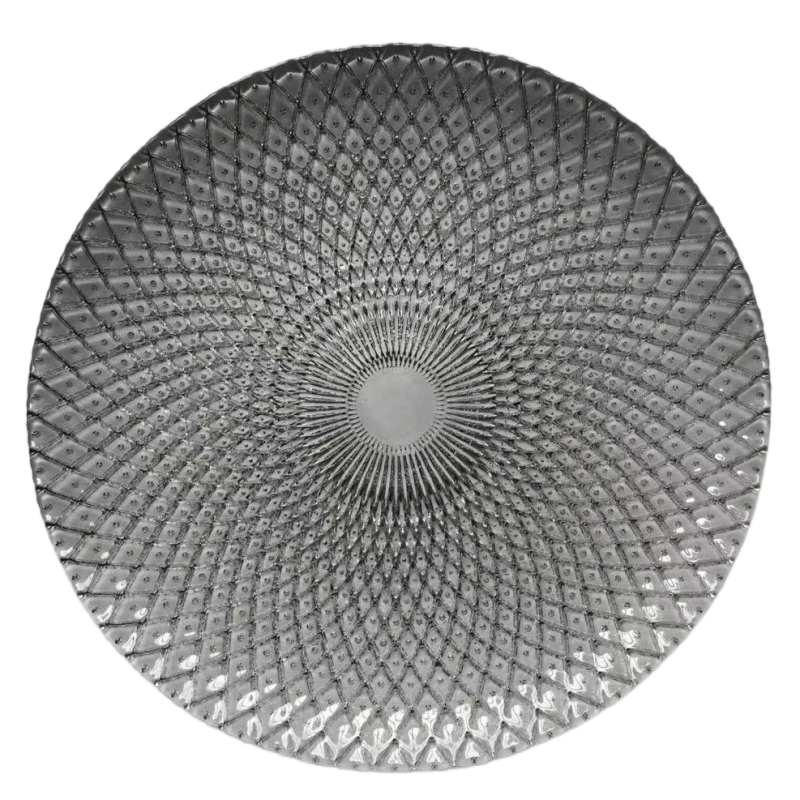

Glass Charger Plates Wholesale

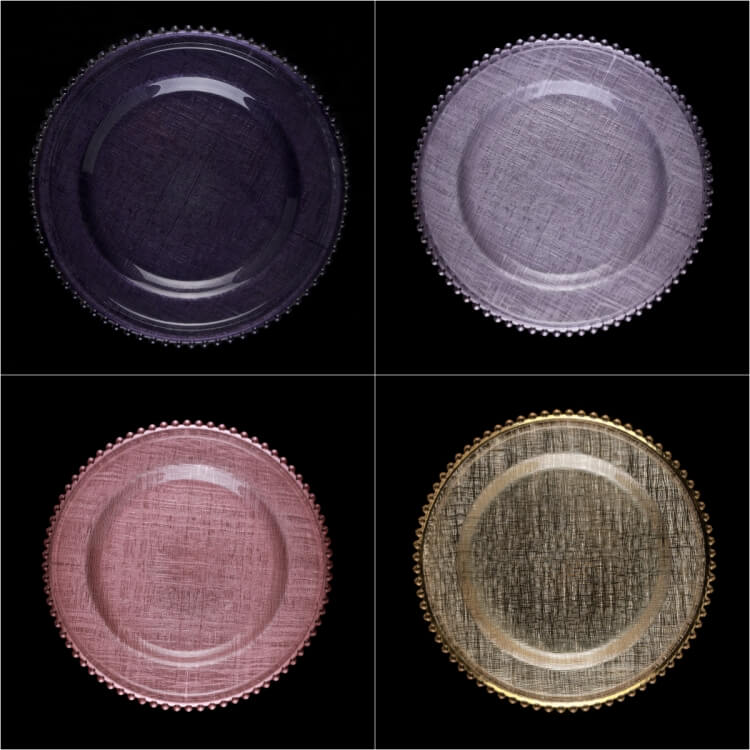

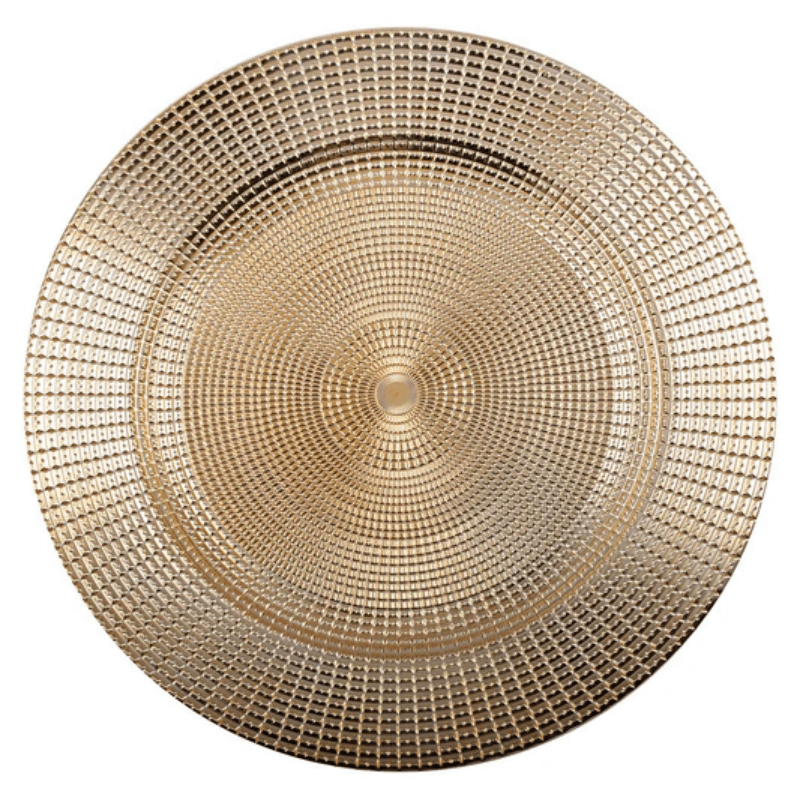

This glass plate is crafted from carefully selected high-quality glass, melted, formed, and annealed at high temperatures to ensure its crystal-clear, durable, and shatter-resistant properties. Its sleek lines and smooth, rounded edges create a delicate feel, combining practicality with aesthetic appeal. We offer a variety of decorative options, including electroplating, spray painting, bordering, and gold foiling, to create a variety of stylish effects. Whether it’s a simple and elegant transparent texture or a luxurious and elegant metallic sheen, we can meet diverse market demands. Glass plates are not only suitable for everyday tableware but are also ideal for wedding banquets, hotels, restaurants, and home decoration. They can also be used as gift plates or display trays to enhance the style and elegance of any space. Available in a variety of shapes and sizes, including round, square, and custom shapes, they fully meet customer needs.

Glass Charger Plates Feature

- Plate size:Regular plates are 33CM, and set plates are 33/27/21CM

- Care and Use: Machine washable up to 25 times, perfect for rentals.

- Pzckage: A box of large size contains 12 pieces, and a box of medium and small size contains 24 pieces.

- Style: Our factory can provide more than 4,000 styles of glass plates

- Production capacity: about 5,000 plates can be produced per day

- Delivery time: Normally 20-30 days

- MOQ: 240pieces

Description

Elevate your table setting and make a statement with glass dinner plates. Each plate is expertly crafted from

premium glass and rimmed with brushed gold leaf for an elegant, modern finish.

Material Collection and Proportioning

Workers accurately calculate the required raw materials based on the customer’s requested plate size and

weight, and then retrieve the appropriate amounts of quartz sand, soda ash, limestone, and other materials

from the raw material warehouse. This ensures the finished product is of the appropriate thickness, minimises

waste, and maintains production efficiency.

Electric Furnace Melting

Weighed raw materials are fed into an electric furnace and melted at a high temperature of approximately

1200°C. Workers monitor the furnace to ensure the raw materials are fully melted, forming a uniform,

transparent glass liquid. They also remove impurities and bubbles during stirring.

Centrifuge Shaping

After the raw materials are placed in a high-temperature kiln to melt into transparent molten glass, workers

pour the appropriate amount of molten glass into a centrifuge mold. The high-speed rotation of the centrifuge

evenly distributes the molten glass within the mold, forming the basic shape of the plate. Different molds can

produce a variety of plate shapes, such as shallow plates, deep plates, and plates with patterns, greatly

enhancing the diversity and precision of the shapes.

Natural Cooling and Annealing

The formed glass discs are briefly cooled in the mold to set their shape. They are then placed in an annealing

lehr, where they are slowly cooled at temperatures between 400°C and 600°C to release internal stress and

prevent cracking or deformation.

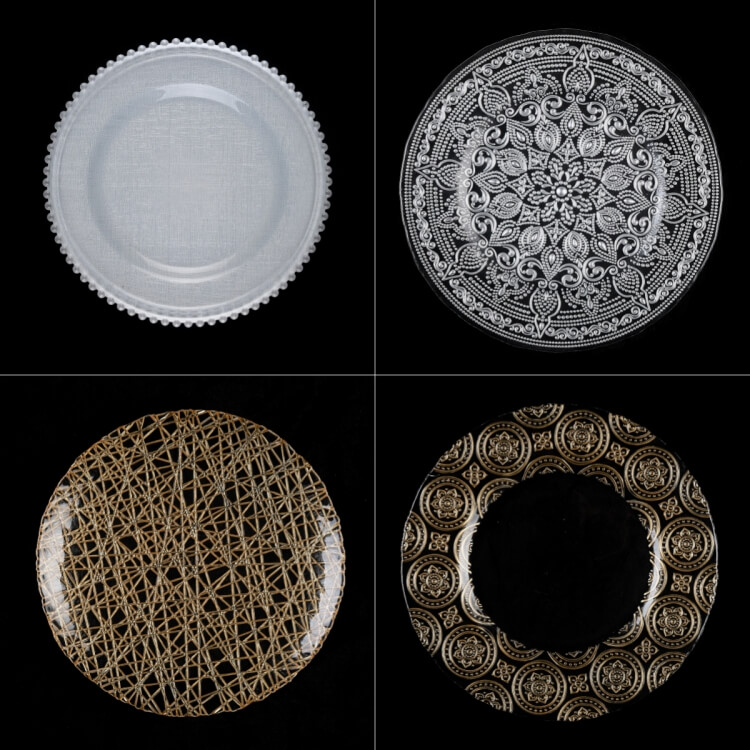

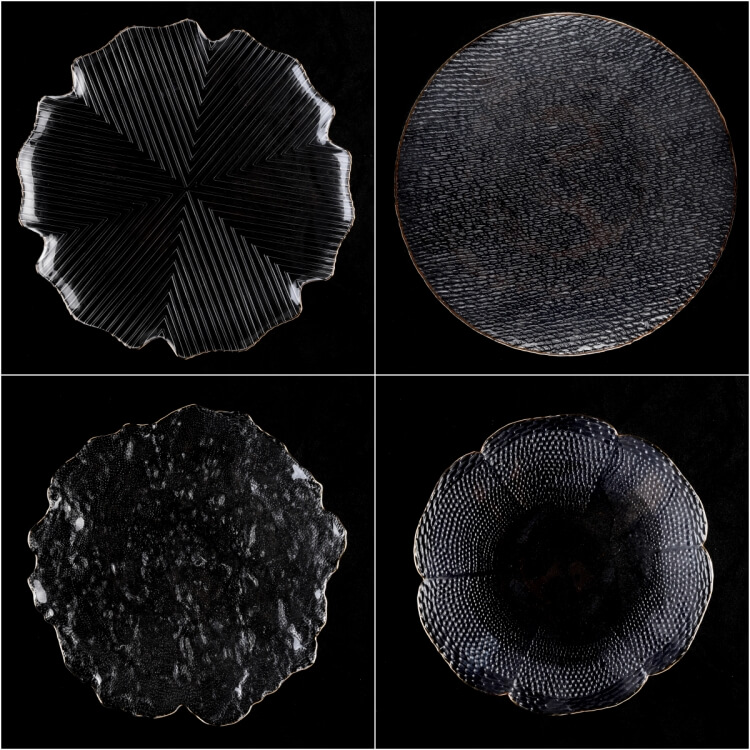

Glass Plate Molds

The molds offer a variety of shapes, including shallow, deep, round, and special-shaped plates, each featuring

exquisite decorative designs such as floral, geometric, and wavy patterns. By injecting high-temperature molten

glass into the mold and subjecting it to a centrifugal spinning process, each plate is precisely formed, with a

clear, three-dimensional surface pattern. This diverse mold range not only meets the needs of diverse scenarios

but also allows for custom shapes and patterns, adding unique personality and beauty to the product.

Cooling and Conveying

After cooling, workers carefully place the finished product onto a conveyor belt, which automatically transports

it to the annealing furnace entrance, where it awaits the first high-temperature annealing step.

The first high temperature annealing, the product enters the high temperature network temperature for the

first high temperature annealing, the finished product is annealed at 600 degrees to ensure that the product

is not easy to explode during use, this step is very important

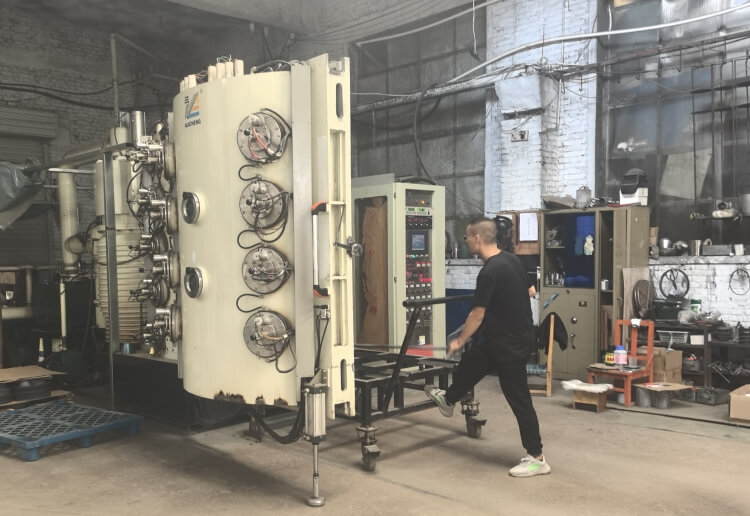

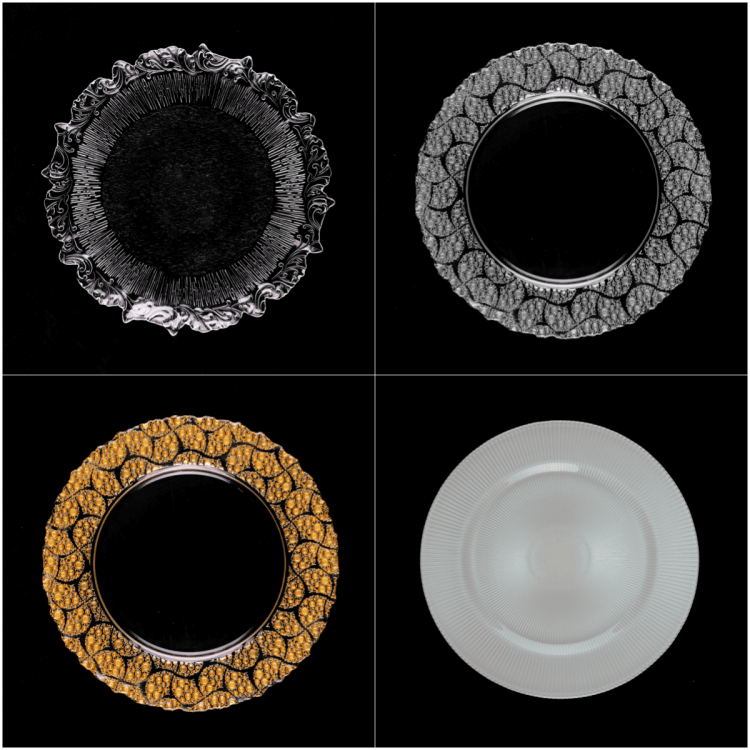

During the glass plate production process, finished products undergo rigorous quality inspection before

entering an electroplating machine for metal plating. This process adds a brilliant metallic effect to the plate’s

surface, enhancing its aesthetics and decorative appeal. Electroplating is suitable for a variety of plate shapes,

whether round, square, or with unique designs, achieving a uniform, refined metal coating, making each

finished product both beautiful and unique.

During the electroplating process, the glass disc is first secured to the electroplating machine’s cathode holder,

ensuring good contact with the power source and a secure position to allow for uniform metal ion deposition.

The electroplating machine’s anode uses a corresponding metal-plated plate (such as silver, aluminum, or copper)

as a source of metal ions. When powered, the metal ions released by the anode migrate through electrolysis

and adhere to the surface of the glass disc, forming a uniform and shiny metal coating. This process can be

controlled by adjusting the current, voltage, and bath temperature, resulting in a glass disc that is both

aesthetically pleasing and durable.

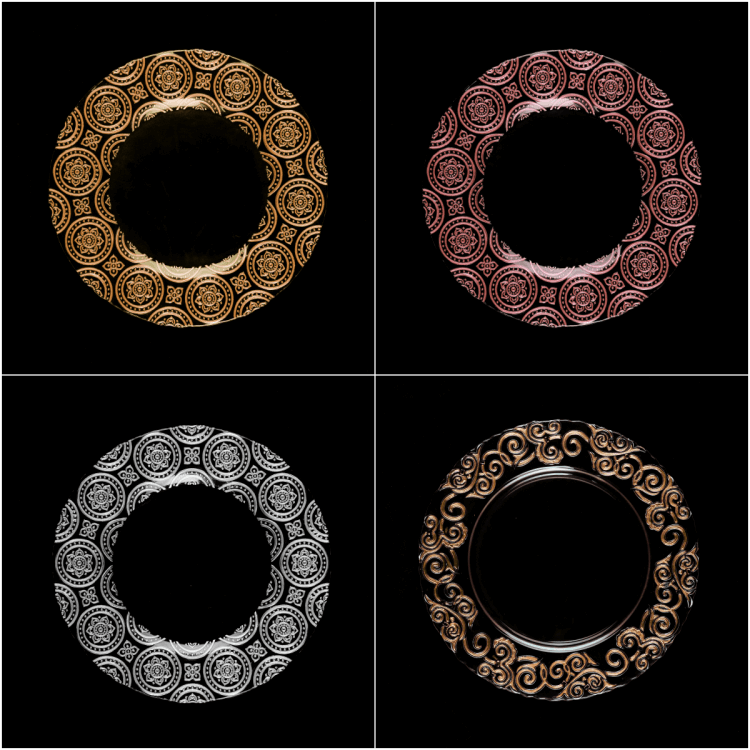

After the metal coating is applied via an electroplating machine, the glass plates can undergo a second finishing

process to create a variety of decorative edge designs based on customer needs. This step not only enhances

the plate’s artistic quality and visual depth, but also adds a personal touch to each product. This process is

often used for display purposes, allowing for a variety of exquisite edge designs to meet the needs of diverse

customers.

Gluing and applying gold foil is a common method used in the decoration of glass plates. First, a thin, even

layer of specialized adhesive is applied to the surface or edges of the plate to be decorated, ensuring a thin,

smooth coating. Next, a thin layer of gold foil is carefully applied over the adhesive layer, gently pressing with

a soft brush or flannel cloth to ensure a firm, complete adhesion and coverage. This process imparts a

gorgeous golden sheen and a refined texture to the plate, enhancing the overall decorative effect.

Gold foil display, gold foil effect can be made according to customer needs, all shapes can have this effect.

Glass Plate Spray Painting Process

The spray-painting process is a common method for decorating glass plates. Depending on the shape and

customer needs, a variety of colors can be applied to the plate surface or edges, creating a rich visual effect.

Not only can conventional popular colors be selected, but customized colors can also be created to meet the

needs of individual styles. The sprayed glass plates achieve a uniform color and delicate texture, adding a

unique artistic atmosphere and decorative value to the finished product.

Our factory boasts a comprehensive production system, offering fast turnaround times, low minimum order

quantities, a wide variety of styles and colors, and support for customization. Whether it’s a standardized

product or personalized needs, we offer flexible options and efficient service to meet diverse needs, including

weddings, banquets, and home decor.

Glass Charger Plates Package

After various post-processing, the finished products to be packaged are packaged accordingly according to

the marks and customers.

After glass plates are produced and pass quality inspection, they undergo a rigorous packaging process.

Each plate is first individually wrapped in bubble wrap or pearl cotton to prevent scratches and collisions

during transportation.

They are then placed in custom-sized cartons or reinforced outer boxes, with partitions or cushioning

materials installed inside to prevent friction between the plates. Depending on customer needs, individual

packaging or multiple sets of plates can be selected for ease of transportation and to ensure the finished

product arrives safely and intact during long-distance transport.

Our plates are available for shipping via two methods: air and sea.

Air: We use thickened styrofoam packaging, which is lightweight and shock-resistant, effectively ensuring

the safety of the plates during transportation.

Sea: We use standard packaging, suitable for large-volume shipments, which is stable, reliable, and cost-effective.

Our plate factory features a spacious and bright showroom showcasing a wide variety of glass plates in various

shapes, colors, and craftsmanship. From classic, minimalist styles to exquisitely customized designs featuring

gilding, hand-painted edges, and spray-painted finishes, the showroom offers a comprehensive selection.

Customers can not only experience the quality and craftsmanship of the products but also select the design

and color that best suits their needs. The showroom’s layout is both artistic and practical, serving as both a

space for product display and a venue for customer discussions and creative exchange.

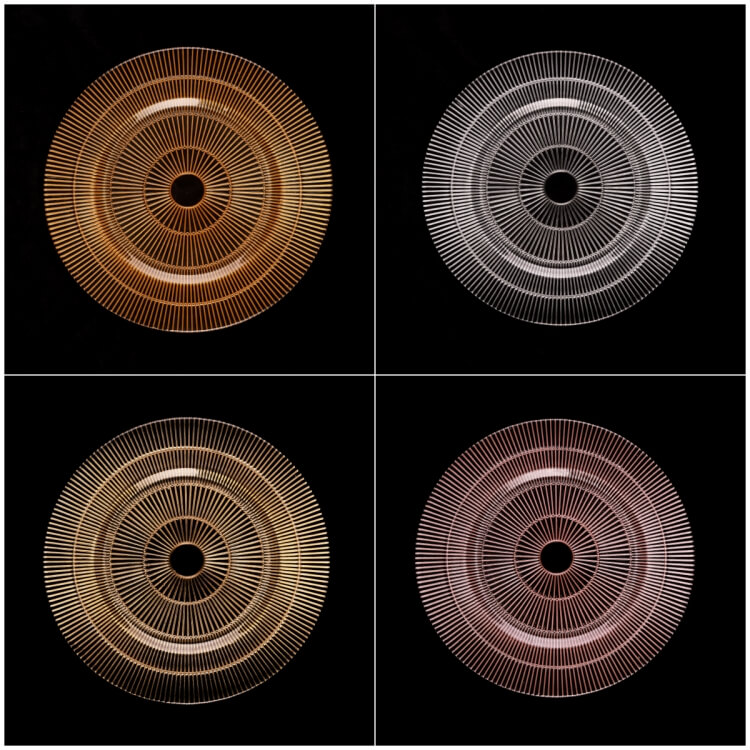

Glass plates are available in a variety of colors and styles

Our plates are renowned for their exquisite craftsmanship and diverse styles, creating an elegant and

sophisticated atmosphere for romantic weddings, grand banquets, and high-end parties. Their durability

and ease of cleaning also make them an ideal choice for the rental market, allowing more events to easily

experience high-quality tableware.

This video showcases the complete production process of our plates. From raw material forming, annealing,

and gilding to hand-drawing, quality inspection, and packaging, every step is meticulously controlled to ensure

the plates are both beautiful and durable. Through this video, you can directly experience the professional

production capabilities of our factory and the high-quality craftsmanship and attention to detail in our products.

Reviews

There are no reviews yet.