Wedding Wine Glass Wholesale

Our wedding wine glasses are made from premium clear glass and produced through hand blown manufacturing combined with refined finishing processes. Each glass features an elegant shape, balanced proportions, and a smooth rounded rim, providing a comfortable drinking experience and a high-end visual appearance. These wine glasses wholesale are widely used for weddings, banquets, hotels, restaurants, and event rentals. With stable quality and consistent sizing, they are suitable for large-volume and long-term supply. Custom services such as logo decals, gold rim decoration, and custom shapes are also available to meet different branding and event needs.

Wedding Wine Glass Feature

- Hand Blown Glass Production: Crafted by experienced artisans for consistent shape and refined details.

- Smooth & Rounded Rim: Fire-polished rim ensures comfort and safety during use.

- High Transparency Glass: Clear appearance with reduced bubbles and flow lines for a premium look.

- Custom Design Available: Support logo decals, printed patterns, gold rim, and custom sizes.

- Strict Quality Control: Inspection standards can be adjusted based on customer requirements.

- Ideal for Wholesale Supply: Factory direct pricing for wedding planners, hotels, and event companies.

Description

Detailed view of the Banquet Wine Glassware

The rim of the wedding wine glass is finely polished and smoothed, resulting in a rounded and smooth edge

that feels natural and comfortable against the lips. The uniform thickness of the rim allows for a more stable

flow of liquid, enhancing the overall drinking experience. It is suitable for frequent use in formal occasions

such as weddings and banquets.

The banquet red wine glass is made of highly transparent glass material, offering excellent clarity, allowing

the color of the wine to be easily seen. The overall design features smooth lines and balanced proportions,

enhancing visual appeal and making it easy to showcase the nuances of the wine under various lighting conditions.

The generous bowl of the glass, with its natural curvature, allows for ample contact between the wine and air,

facilitating the release and concentration of aromas. This design enhances the flavour characteristics of both

red wines and wines served at banquets.

The stem of the wedding wine glass is slender yet structurally stable, with reinforced connections, resulting

in excellent overall balance. When placed on a banquet table or as part of wedding decorations, it remains

stable and does not wobble, combining both aesthetics and practicality.

How are high-quality glass wine glasses manufactured?

-

High-Temperature Electric Furnace Material Extraction

Glass raw materials are fully melted in a high-temperature electric furnace at approximately 1200°C, forming

a transparent and uniform glass liquid. Once the glass reaches a stable state, experienced workers precisely

extract the material, ensuring consistent quantities each time, laying a solid foundation for subsequent cup

shaping.

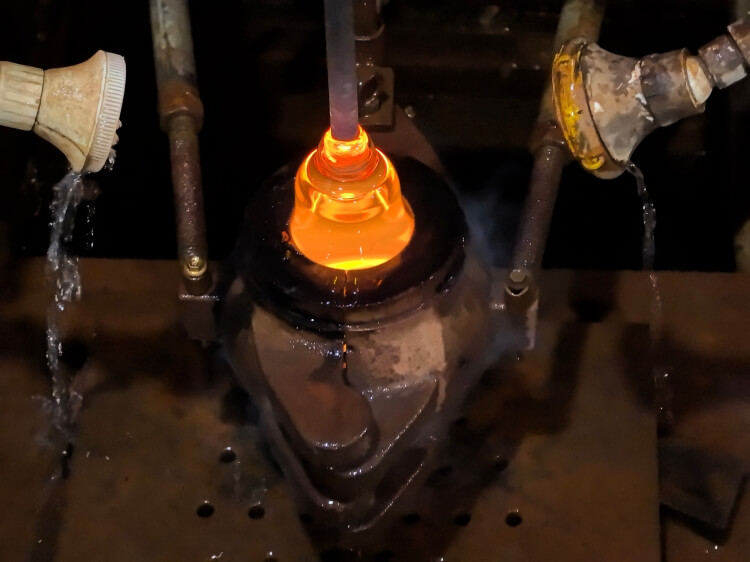

Mold Cooling and Shaping

The formed glass material is placed in a special mold for cooling and shaping. Through controlled cooling,

the process effectively reduces air bubbles and flow lines within the glass, resulting in a more transparent

and uniform cup body with a more refined overall appearance.

Mold Cooling Treatment

The formed glass bubbles are placed into a special mold and precisely cooled with cold water. This effectively

reduces water marks and air bubbles in the glass, making it more transparent and lustrous, thus improving

the overall texture and aesthetics.

Exclusive Mold Design

Each cup is made with an exclusive mold. The molten glass is precisely poured into the mold, and the cup’s

shape is formed through the mold’s design and controlled manufacturing process. This ensures that each cup

has consistent dimensions, smooth lines, and a beautiful, refined appearance.

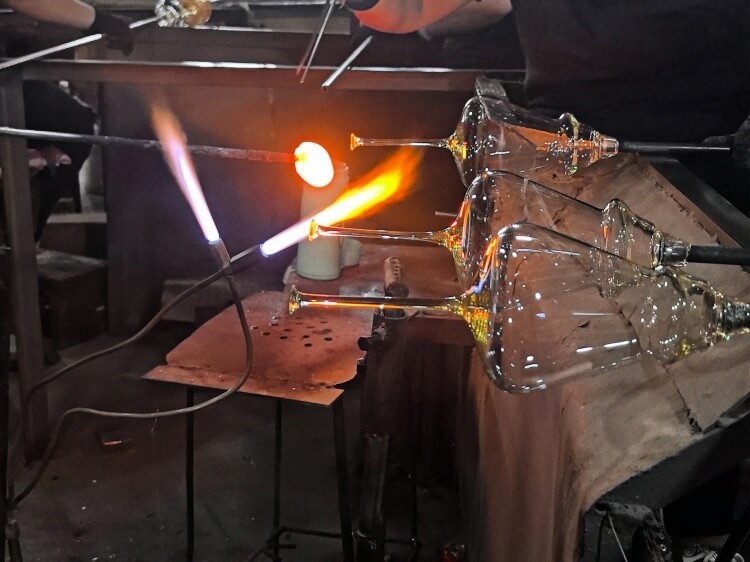

High-Temperature Stretching Treatment

After being removed from the mold, the wine glasses undergo a high-temperature stretching treatment.

Through precise heating and controlled stretching, the shape of the glass becomes more stable and the lines

more fluid. This process also enhances the glass’s strength and overall quality, ensuring that each wine glass

is both beautiful and durable.

Handcrafted High-Temperature Shaping

After the wine glasses are removed from the mold, experienced craftsmen manually shape them at high

temperatures. Through years of expertise, they precisely control the shape and thickness variations of the glass,

ensuring that each wine glass has smooth lines and perfect proportions. This process not only enhances the

durability of the wine glasses but also showcases the unique craftsmanship and quality of handmade products.

Bottom Connection Processing

After the stem of the wine glass is completed, the bottom connection will be processed to ensure a perfect

and secure fusion of the base and the body of the glass, while maintaining smooth and elegant overall lines.

This lays a good foundation for subsequent annealing and polishing.

Bottom Attachment and Adjustment

After the stem of the wine glass is completed, a suitable amount of glass material is taken to attach the base.

The size and shape of the base are precisely adjusted manually to ensure a tight and seamless connection

between the base and the body of the glass, maintaining stability and aesthetics, and preparing it for

subsequent annealing and polishing.

Rod Removal and Annealing Preparation

After all the hand-blowing and stretching processes are completed, the operating rod used for blowing is

removed, ensuring the commercial wine glass maintains its complete and undamaged shape. The wine glass

is then placed in a high-temperature annealing kiln for slow cooling, which releases internal stress and

improves the glass’s strength and durability.

Mouth Finishing (Rim Trimming)

After emerging from the high-temperature annealing furnace, the wine glasses are still semi-finished products.

They undergo a rim trimming process based on the required rim diameter and glass height. This removes excess

material, resulting in a flat and smooth rim with precise dimensions. This prepares the glasses for subsequent

grinding and polishing, while also enhancing their overall aesthetics and functionality.

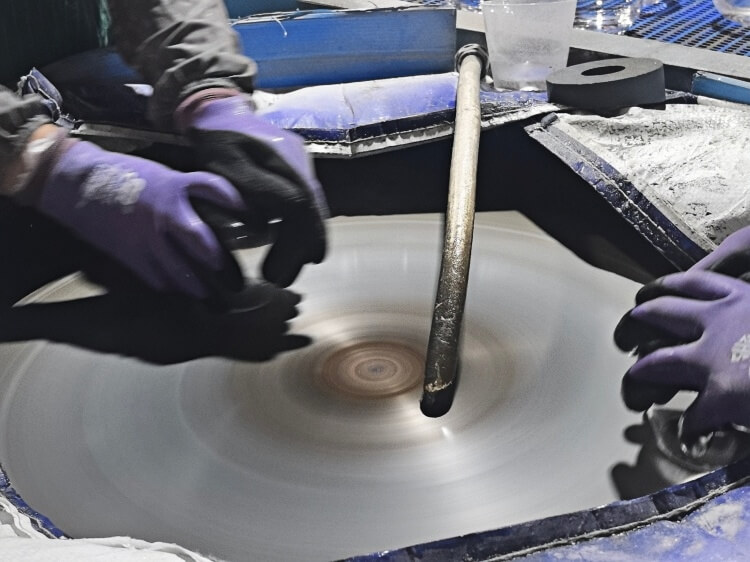

Edge Grinding Treatment

After the glass blowing process is complete, the rim of the wine glass may have uneven surfaces. Edge grinding

treatment is necessary to smooth and flatten the rim, preparing it for the subsequent inner beveling process

and improving the overall feel and visual appeal of the wine glass.

Inner Edge Chamfering

After the grinding process is complete, the rim of the wine glass undergoes an inner edge chamfering process.

This makes the rim smooth and rounded, without any sharp edges, which not only improves safety during use

but also makes the overall design more refined and aesthetically pleasing, highlighting the quality of handcrafted

workmanship.

Cleaning and Edge Finishing Preparation

After the grinding process is complete, the rim of the wine glass may have trace amounts of residue. It needs

to be thoroughly cleaned with purified water to ensure the glass surface is clean and free of impurities.

After cleaning, the wine glass proceeds to the edge finishing process, ensuring the rim is smooth and bright

during this treatment, laying the foundation for the final polishing and finished product quality.

Low-temperature drying

After cleaning, the wine glasses are placed on a low-temperature drying rack to thoroughly remove water

stains from the body and rim of the glass, ensuring the glasses are completely dry. This provides a clean

surface for subsequent edging, grinding, and polishing, guaranteeing the quality and luster of the finished

product.

Rim Finishing

After the inner rim is formed, the wine glass rim undergoes a high-temperature finishing process. Through

precise control of temperature and pressure, the rim achieves the ideal smooth and rounded finish. This process

is performed manually by experienced craftsmen, ensuring that each wine glass rim is both aesthetically pleasing

and safe, while showcasing the exquisite craftsmanship and quality of handmade production.

Quality Inspection

Every wine glass undergoes rigorous quality inspection before leaving the factory. The inspection standards

can be flexibly adjusted according to the requirements of different customers. The main checks include

transparency, bubbles, scratches, rim flatness, and overall dimensions, ensuring that each wine glass meets

the customer’s customized standards and satisfies the high-quality requirements for weddings, banquets,

and other events.

Finished Product Inspection and Stacking

Wine glasses that have passed quality inspection are neatly stacked in the finished product inspection and

stacking area, ensuring the safety of the glasses and preventing collisions, thus preparing them for subsequent

packaging and shipping. The stacking is standardized and orderly, ensuring that each wine glass remains in

perfect condition during storage and transportation.

Inspected Product Staging Area

Wine glasses that have passed quality inspection are neatly stacked in the inspected product area. They are

clearly separated into acceptable and defective items based on the inspection results, ensuring that acceptable

products are safely stored for subsequent packaging and shipping, while also facilitating rework or disposal of

defective items, guaranteeing consistent product quality before shipment.

Gold Rimming Technique

All wine glass styles can be treated with gold rimming. A delicate gold line is meticulously applied to the rim of

the glass, enhancing the overall elegant and sophisticated visual appeal and showcasing the exquisite craftsmanship.

This technique is particularly suitable for high-end occasions such as weddings and banquets.

Decal Application Process

Wine glasses can be personalized with custom decals according to customer requirements. Experienced

workers hand-apply the decals to the designated areas on the glass, and then the design is fixed through

baking, ensuring a durable and long-lasting decorative pattern. This process results in beautiful and unique

glasses, meeting the high-quality demands of weddings, banquets, and customized gifts.

Finished Wine Glass Inspection and Packaging Preparation

This process involves the final inspection and packaging of wine glasses before they leave the factory. All

wine glasses are neatly arranged on the workbench, and workers inspect each glass individually, checking for

clarity, rim integrity, and overall consistency. After passing inspection, the wine glasses are packaged using

bubble wrap, pearl cotton, and paper for layered protection, effectively preventing collisions and scratches

during transportation and ensuring the products arrive safely to the customer. This process is suitable for

wedding, banquet, and bulk wholesale orders.

Specialized Wine Glass Storage Boxes

We also offer specialized storage boxes for storing and transporting wine glasses. These boxes feature

intelligently designed compartments to accommodate different glass types and sizes, effectively securing the

glasses and reducing collisions and damage during handling and transportation. These storage boxes are ideal

for wedding companies, event rental businesses, and warehousing and logistics operations, facilitating organized

management and repeated use, further enhancing overall efficiency and safety.

Dedicated Glassware Showroom

We have a dedicated product showroom to showcase our factory’s main and newly developed glassware

and glass products. The showroom is systematically arranged according to different glass types, usage scenarios,

and design styles, including wedding glasses, banquet glasses, champagne flutes, water glasses, and various

custom designs. This allows customers to easily compare shapes, rim craftsmanship, glass clarity, and overall quality.

At the wedding venue, wine glasses were neatly arranged on banquet tables covered with white tablecloths,

reflecting a clear and soft luster under the light and surrounded by flowers. When guests raised their glasses

to toast, the rims were smooth and delicate, comfortable to the touch, showcasing quality in every detail.

Whether in the welcome champagne area, at the main banquet tables, or during the toasting ceremony and

dinner reception, these wine glasses seamlessly blended into the wedding atmosphere, enhancing the overall

ambiance and making every toast a memorable moment.

Reviews

There are no reviews yet.