Resin Stacking Chair Manufacturer

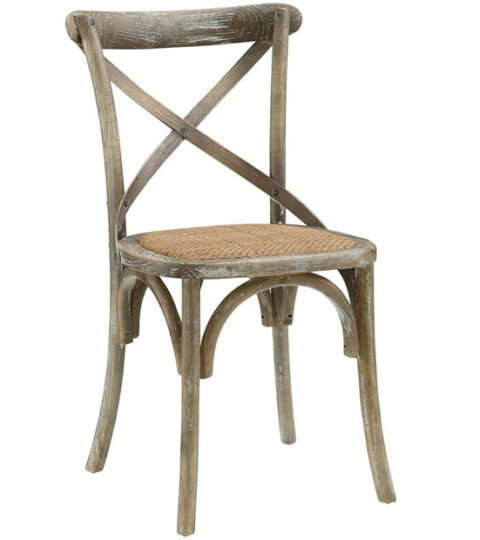

The resin Sonet chair is a popular high-end event chair that is favoured for its classic appearance and superior performance. Made of high-quality resin material, this chair imitates the appearance of the traditional wooden Sonet chair but is lighter and more durable. With its elegant lines and exquisite design, the resin Sonet chair is an ideal choice for important occasions such as weddings, banquets, and meetings, and can add a sense of nobility and elegance to various decorative styles. Resin Sonet chairs not only have excellent durability and can resist daily wear and weather, but also have the advantages of being easy to clean and maintain. Their smooth surface makes cleaning easy and simple, just wipe it gently with a damp cloth. In addition, this chair is lightweight and easy to carry and stack, which greatly saves storage space and layout time. Made of environmentally friendly resin materials, the resin Sonet chair is not only safe and non-toxic but also has a special anti-ultraviolet treatment, which can maintain a bright and new appearance for a long time. Whether it is an outdoor garden wedding, a luxurious banquet hall, or a stylish conference room, the resin Sonet chair can be perfectly integrated, providing a comfortable sitting feeling and elegant visual effects. It is an indispensable seating choice for all kinds of high-end event occasions.

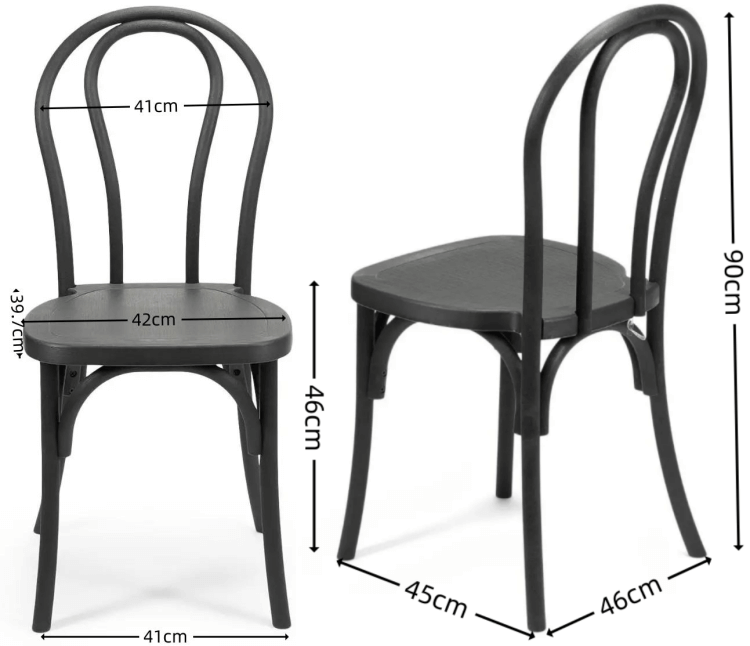

Resin Thonet Chair Feature:

- Perfect for entertaining guests in the kitchen, dining room, patio, garden or poolside deck

- Add style to your space year-round thanks to its weather-resistant construction.

- Made of resin, it has a realistic wood look that won’t fade and doesn’t require the regular maintenance of real wood.

- Lightweight construction allows for easy movement and storage.

- Each chair has a static load capacity of 1,000 lbs.

- Use a dry cloth, water and foaming cleaner for quick and easy maintenance.

- The resin stacking chairs are stackable and save a lot of space

Description

We can also provide a variety of popular resin stacking chairs in various colours, such as white, black,

and natural wood, to meet the needs of different occasions and decoration styles. These diverse colour

options make the chairs more flexible and adaptable and can be perfectly integrated into various weddings,

banquets and events. Whether a classic, modern or natural style, it can be easily matched to enhance the

overall atmosphere. Whether you are looking for pure white, fashionable black, or warm natural wood colour,

we can provide you with the right choice to make every event full of personality and beauty.

We use imported resin materials, which usually have strong resistance to UV rays, high temperatures and ageing,

and are not prone to fading, cracking or deformation due to long-term exposure to sunlight or other harsh

environments.

The process of producing resin stackable chairs begins with a design drawing. The designer makes a detailed design

based on the classic style of the Thonet chair, including every detail of the chair’s size, shape and structure.

Next, precise moulds are made according to the design drawings. These moulds are usually made of metals

such as steel or aluminium to ensure consistency and precision in every chair part. The high accuracy and

durability of the mould are important factors in ensuring the quality of the resin stacking chair.

The production process of resin stackable chairs begins with the selection of raw materials. High-quality imported

resin materials such as polypropylene (PP), polycarbonate (PC) or glass fibre-reinforced resin are selected,

which are known for their durability, lightness and environmental protection. Next, according to the design

requirements of the chair, the selected resin material is mixed with colour additives to obtain the desired

colour and transparency, thereby meeting the aesthetic and functional needs of the design.

In the production process of resin stackable chairs, the resin pellets are first heated under high-temperature conditions

until they are completely melted into a liquid state. Next, the melted resin material is injected into the mould

through an injection moulding machine to ensure that the material evenly fills the cavity to achieve a

precise shape and thickness. After the injection moulding is completed, the mould is cooled to allow the resin

material to gradually solidify and form. The cooling time needs to be precisely controlled according to the

material’s characteristics and thickness to ensure the finished product’s quality and consistency.

The outdoor resin stack chair is removed from the mould when the cooling and curing are complete. The

next step is to trim and deburr to remove any excess edges or mould lines to ensure a smooth and flawless

surface. This process may require manual trimming and mechanical grinding to achieve perfect surface quality.

During the surface treatment stage, the resin stacking chair can be sprayed or polished according to needs

to improve its glossiness and protection. In addition, to enhance the chair’s anti-ultraviolet and anti-ageing

properties and make it more suitable for outdoor use, some resin chairs will undergo special weather

resistance treatment. Through these surface treatments, the beauty and durability of the rein-stacking chair

are further improved.

If the outdoor resin stack chair design includes multiple parts (such as the backrest, legs, seat cushion, etc.),

the assembly and fixing stage is to assemble the parts. By using screws or special connectors, these parts

are firmly combined to ensure that the overall structure of the chair is strong and meets the design requirements.

The resin bentwood chairs are rigorously tested during production to ensure the quality and stability of each chair.

We conduct multiple tests on the chairs, including load-bearing capacity, durability, impact resistance, etc.,

to ensure that the chairs perform well in a variety of use occasions. Each chair is carefully inspected to

ensure that it can provide guests with a safe and comfortable sitting experience, whether it is a wedding,

banquet or other high-end event. Through these manual tests, we ensure that the resin stackable chairs

meet high standards of quality and provide customers with reliable product choices.

Each stacking chair will undergo strict quality inspection before leaving the factory to ensure that its appearance,

structure and function fully meet the design standards. Through careful inspection, it is ensured that the chair

has no defects, ensuring its beauty, stability and safety in use, to meet the high-quality product requirements.

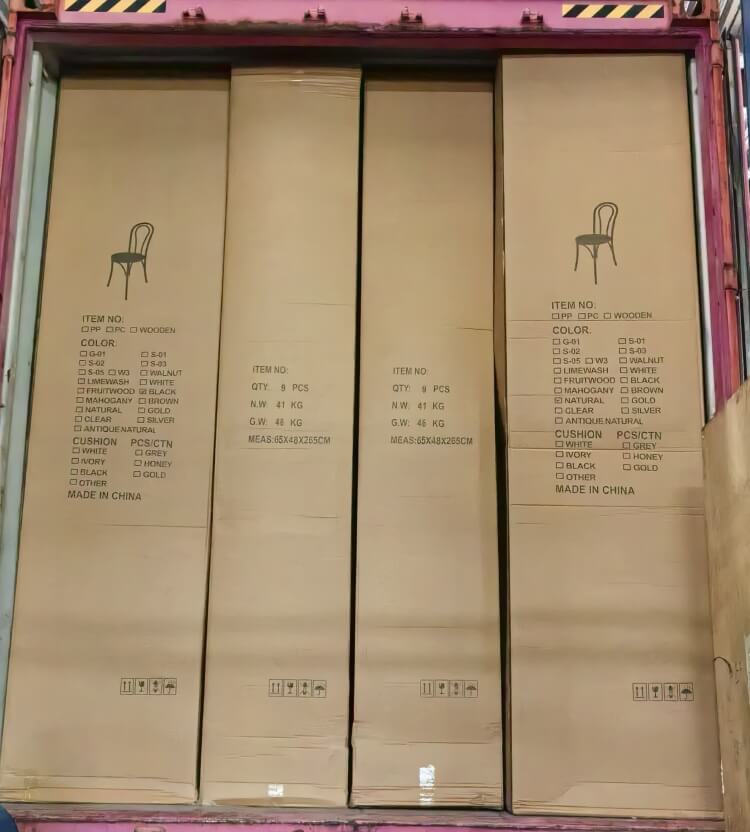

During the packaging and shipping phase, the stacking chairs are carefully packed, usually using protective

materials such as bubble wrap, plastic film or cartons to prevent damage during transportation. Once packed,

the stacking chairs are transported to a warehouse for storage or directly delivered to the customer, ensuring

that the product arrives at its destination in perfect condition.

We offer a variety of packaging options to meet the needs of different customers. Chairs can be packed in

cartons to ensure extra protection during transportation, or they can be packed naked, which is suitable for

occasions that require fast loading and unloading and space-saving. No matter which packaging method is

used, we are committed to providing you with a convenient and efficient solution to ensure the safety and

integrity of the product during transportation and storage.

Packaging Dimensions: 65*48*265CM (full pack), 10 pieces/box

Perfect for use at home in your kitchen, dining room, sunroom or garden, or on your patio, porch or deck,

this chair is also suitable for commercial use and is an ideal addition to your business. Impress your

customers and add a warm, calming touch to your restaurant, bar, bistro, cafe, lounge, hotel or any other

high-traffic venue where providing a top-notch experience is essential.

Reviews

There are no reviews yet.