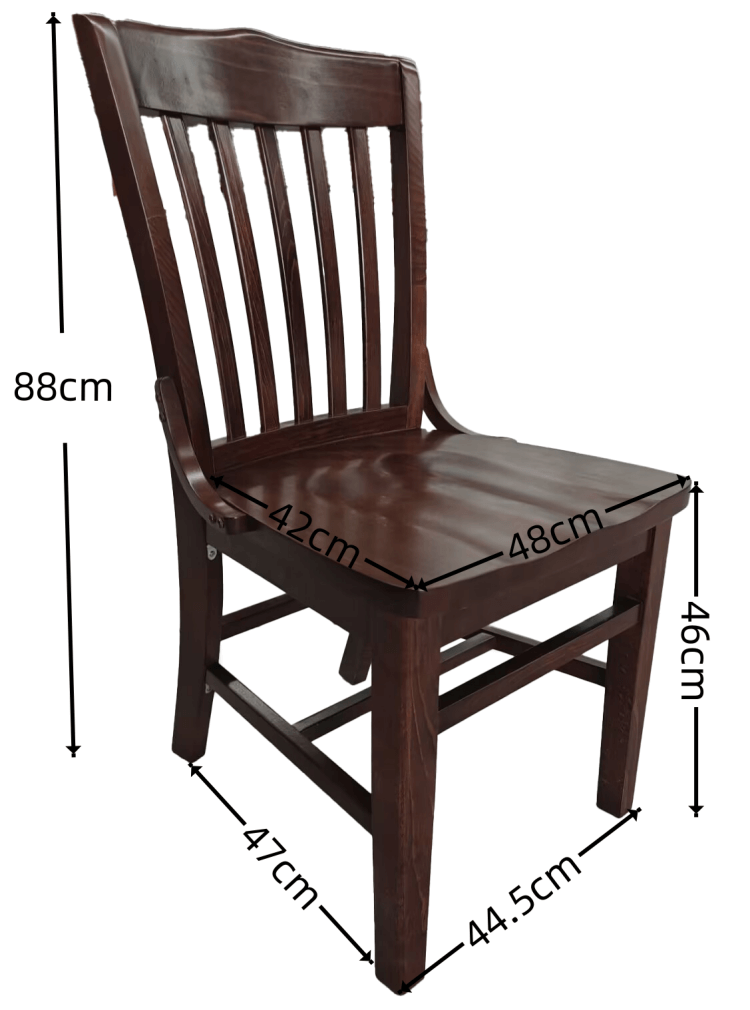

School House Back Mahogany Wood Dining Chair

This solid wood dining chair is made of traditional craftsmanship. The overall shape is stable and generous, showing a strong American retro style. The chair back design features a curved top with a vertical backrest, which is not only aesthetically pleasing but also ergonomically designed to effectively support the back and enhance sitting comfort. The seat is wide and thick, with a natural and smooth surface texture that showcases the warmth and texture of solid wood. The armrests on both sides are slightly expanded, which enhances the stability and sense of security when in use. It is suitable for matching various dining tables and is widely used in family restaurants, retro theme restaurants and high-end clubs, adding elegance and calmness to the environment.

School House Back Mahogany Wood Dining Chair Feature

- Solid European beech hardwood construction

- Tension and mortise and tenon construction with metal wood screws for reinforced legs

- Colour: Mahogany

- 800 lbs. weight capacity

- Assembly required: No

- Overall dimensions: 18.5″ W x 21.5″ D x 35″ H

- Seat Board: solid beech wood 28 mm thick

Description

-

School House Back Mahogany Wood Dining Chair Detail

This wooden dining chair is equipped with sturdy support legs and durable floor rails, which excel in structural

stability and ease of use. Each support leg is thickened and reinforced to ensure an overall load-bearing capacity

of up to 800 pounds (approximately 360 kg), making it suitable for users of all sizes and high-frequency

commercial use scenarios, such as restaurants, banquet halls, and conference venues.

The anti-scratch floor rails installed at the bottom can not only effectively protect floor materials such as wooden

floors, tiles or carpets from scratches, but also improve the smoothness and quietness of the chair’s movement.

The rails are made of high-strength plastic material, which is wear-resistant and not easy to fall off. Even during

repeated dragging or transportation, the chair can be kept stable and not shaken.

-

How is the School House Back Mahogany Wood Dining Chair produced?

The School House Back Mahogany Wood Dining Chair is produced through a meticulous process that blends traditional

woodworking craftsmanship with modern machinery. Here’s a detailed overview of the manufacturing process:

-

Durable Wooden Frame, Stable and Reliable

This wood dining chair features a high-quality European beech wood frame. Its excellent hardness and density

provide the entire chair with extremely high structural strength and stability. The beech wood has a fine and

uniform texture, which not only looks natural and beautiful but also exhibits excellent compression resistance,

ensuring this chair remains as strong as ever in daily high-frequency use.

In terms of structural design, the chair has a reinforced crossbar between the four legs, which greatly

enhances the overall load-bearing capacity and can easily withstand up to 350 pounds (about 150 kilograms)

of weight, meeting the needs of various users without shaking or deformation. At the same time, the support

design on both sides of the seat further improves stability, maintaining excellent durability even in busy

commercial environments or large gatherings.

To ensure the stability and durability of the wood, we strictly dry each log. First, the log will be placed in a

well-ventilated drying area for natural air drying for several months to slowly release the moisture inside the

wood and reduce its internal stress. After that, the initially dried wood will be sent to a constant temperature

drying room for deep dehydration under controlled temperature and humidity conditions. This will greatly

reduce the cracking, deformation, insect infestation and other problems of the wood during later processing or use.

We use efficient and accurate automatic sawing machines for cutting operations. According to the CAD design

drawings, the cutting parameters are set, and the automatic sawing machine can accurately cut each piece of

wood into various parts of the chair, including chair legs, cross braces, chair back bars, seat panels, armrests,

etc., to ensure that the size error of each component is controlled within a very small range.

The automated cutting process not only significantly improves production efficiency but also ensures the

perfect fit between all parts, laying the foundation for subsequent assembly and structural firmness. Compared

with traditional manual cutting, automated equipment has higher consistency and repeatability, effectively

avoiding human errors and material waste, and is an indispensable part of the manufacture of high-quality

wooden chairs.

In order to create a curved chair back that fits the curves of the human body, we use a combination of traditional

and modern wood bending techniques. First, the wood strips required for the chair back are placed in a steam

box and heated at high temperature to soften the wood fibers and make them flexible and plastic. Then,

the wood strips are quickly placed in a metal mold while still hot for bending, and the molds are pressed and

shaped according to the designed angles. They are fixed and cooled in the mold for more than 24 hours

to gradually shape them. Finally, the bent parts after demolding need to be naturally cured in a ventilated

environment to release internal stress and prevent rebound or deformation in the later stage, thereby

ensuring the beautiful lines and stable structure of the chair back.

Hydraulic hot press for laminating boards. This equipment is widely used to splice multiple dried solid wood

boards into a thick, stable, seamless composite board by applying high temperature and high pressure. It is

mainly used to make the seat, backrest or other load-bearing parts of chairs.

During the operation, the wooden boards pre-coated with environmentally friendly glue are first stacked layer

by layer and placed on the work surface of the press. Then, multiple sets of hydraulic pressing arms on the

equipment are activated, evenly applying several tons of pressure downward to ensure that each layer of the

board fits tightly and has no bubbles or gaps. At the same time, the internal heating system of the press is

activated to heat the pressing plate to the set temperature. The high temperature can quickly activate the glue

and penetrate the wood fibers to complete deep bonding. This process not only improves the firmness and

crack resistance of the entire board, but also effectively avoids the deformation, warping and other problems

caused by using a whole piece of log.

Behind the press is a high stack of press arms, which are used to process multiple groups of boards at the

same time to improve production efficiency. The wooden planks neatly placed in front have completed the

initial cutting and seaming, and are waiting to enter the press for the next step of bonding and pressing.

The boards processed through this process not only have high surface flatness and strong pressure resistance,

but also show better stability in subsequent processing such as carving, punching, and painting. It is a key step

to ensure the durability and structural safety of the entire solid wood chair.

In the spraying workshop, a batch of solid wood dining chair frames is being sprayed or dried. The

wooden dining chair frames are neatly arranged on a special wooden rack for uniform spraying and natural

drying. Each chair features a bent wood structure and a curved backrest design, which is both aesthetically

pleasing and ergonomically designed. The entire workshop environment is well ventilated and equipped with

professional spraying equipment and exhaust systems to ensure the safety and efficiency of the spraying

process. This batch of chairs has a uniform overall colour and presents a warm wood lustre, which is suitable

for high-end places such as banquets and restaurants.

-

Fine Grinding

Use coarse-grained sandpaper or sanding belt for preliminary treatment, the main purpose is to remove burrs,

saw marks and glue residue on the wood surface, and trim the edges and contours to make the lines of the

entire chair frame is more regular and smooth. Then use higher-grit (finer) sandpaper to polish the carefully

entire chair surface, especially the seat, armrests, backrests and other parts that come into direct contact

With the human body, to ensure a smooth touch and no roughness, and to improve the overall texture.

During the entire polishing process, the factory uses a combination of mechanical equipment and manual

polishing. Large flat parts are usually processed efficiently by machines, while complex curved surfaces,

curved chair backs, chair leg joints and other detailed areas are polished manually by experienced workers

to ensure that every corner has a natural transition, no sharp edges, and does not hurt the hands.

The main connection parts of the chair (such as between the legs and the cross brace, and between the

backrest and the seat frame) usually adopt the mortise and tenon structure. Through CNC machining (CNC),

the tenoning is precisely cut to ensure that every tenon and mortise fits perfectly, so that the structure can

remain highly stable without a large number of metal parts. The mortise and tenon connection not only

enhances the load-bearing capacity but also effectively prevents loosening and deformation during long-term

use, fully continuing the wisdom of Chinese woodworking craftsmanship.

Throughout the chair manufacturing process, the use of environmentally friendly glue is a key step in ensuring

product safety and environmental friendliness. All processes involving bonding, including seat panel splicing,

chair back lamination, structural reinforcement, etc., use high-grade glue that has passed environmental tests

certification, effectively avoiding the release of formaldehyde and other harmful volatiles commonly found

In traditional adhesives.

-

Wood Dining Chair Package

Customers can choose water-based paint according to their needs, which is more environmentally friendly.

quick-drying, and matte and natural, or choose PU paint (polyurethane paint), which has stronger wear

resistance and gloss performance and is suitable for occasions that require high intensity of use. In terms of

colour, we provide a variety of classic wood colours, such as walnut, black, and log colour, and can also

customise the colour according to the customer’s preferences and space style.

Naked stacking packaging is an efficient logistics method suitable for customers who have strict requirements

on transportation costs and space utilisation. By stacking multiple chairs neatly and orderly, without the need

for individual cartons, the volume can be compressed to the maximum extent, thus significantly reducing

transportation costs, which is especially suitable for container transportation or bulk purchase scenarios.

Before stacking, each chair will still be wrapped with foam paper and plastic bags to effectively prevent the

surface from being scratched or bumped during transportation. We will also place cushioning materials

reasonably according to the structure of the chair and the stacking height to ensure the overall stability and

safety after stacking.

The walnut-colored, environmentally friendly paint finish has natural and clear wood grain and a warm and

elegant colour, which not only enhances the overall texture but also makes it suitable for various scenes,

such as restaurants, hotels, banquet halls, cafes, etc. When placed in front of a sunny glass window, it creates

a warm and comfortable atmosphere. It is a classic solid wood chair that combines practicality and beauty.

Reviews

There are no reviews yet.