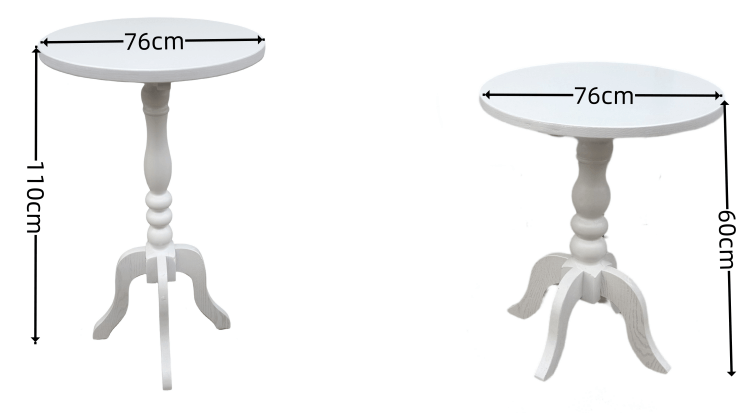

Wooden Bar Furniture Supplier

This wedding bar table is carefully crafted with selected high-quality wood, which not only ensures a sturdy and durable structure but also shows a classic European design style, perfectly blending the beauty of elegance and practicality. The tabletop is made of high-strength wood and has undergone strict woodworking processes, including splicing reinforcement, fine grinding, and environmentally friendly water-based paint spraying, making its surface smooth and delicate, warm to the touch, and has excellent wear resistance and moisture resistance, ensuring that it can remain beautiful as new after long-term use. With its excellent craftsmanship and high-end and elegant design, this table is widely used in wedding banquets, banquet halls, high-end restaurants, hotels and other places. It not only provides a stable and durable use experience, but also greatly enhances the overall style of the venue, showing a unique taste and sense of dignity. Whether it is a formal banquet or daily dining, this table is an ideal choice, perfectly balancing beauty and practicality.

Wooden Wedding Bar Table Feature

- Select high-quality wood with strong load-bearing capacity and that is not easy to deform, ensuring stability and durability for long-term use.

- Using environmentally friendly water-based paint and electrostatic spraying technology, the paint surface is smooth and delicate, without pungent odor, safe, healthy, wear-resistant and moisture-proof.

- It adopts a detachable structure to reduce transportation volume and logistics costs and is equipped with installation hardware for easy and quick assembly.

- It is suitable for different occasions such as wedding banquets, high-end restaurants, cafes, etc. It is both decorative and practical.

Description

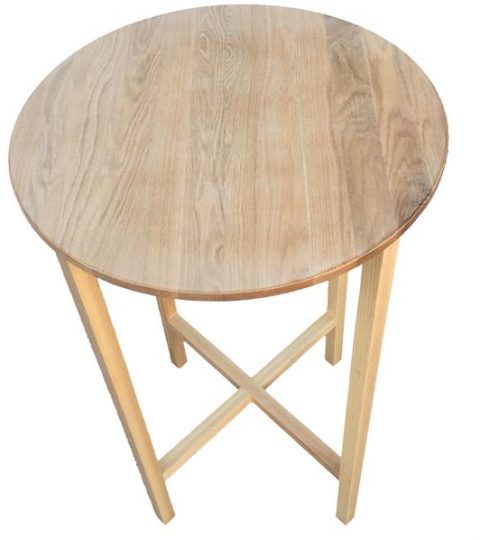

Before production, we must select high-quality wood, such as oak, birch or pine. These woods are

hard and have good load-bearing capacity and durability. We will ensure that the wood has no cracks,

insect bites or apparent knots to ensure the beauty and durability of the finished product.

After selecting the right wood board, check its surface finish, thickness and wood grain direction to

ensure it meets the processing requirements. Then, a CNC engraving machine or woodworking saw

table accurately cuts the wood into a circular tabletop according to the preset size and design requirements.

During the operation of the CNC engraving machine, the tool path is controlled by the computer to ensure

smooth edges and accurate dimensions. When using a woodworking saw table, it is necessary to use a

compass or template to mark and use a fine-cutting process to ensure that the edges of the circular tabletop

are even and flat. After the cutting is completed, the tabletop needs to be polished to remove burrs and make

its surface smoother, ready for subsequent processing and painting.

After rough processing, the tabletop needs to be finely sanded and trimmed to ensure the quality and

aesthetics of the final product. First, use coarse sandpaper to perform preliminary sanding on the edges of

the tabletop to remove burrs and uneven parts that may remain during the cutting process and make the

outline smoother. Then, use finer sandpaper to polish the entire tabletop surface to improve smoothness

and reduce minor scratches. In addition, for wooden tabletops, you can wipe the sanded surface with a

damp cloth to detect whether there is still a sense of roughness and ensure that every detail

is handled properly. After sanding, the tabletop will have a uniform and delicate texture, which is fully

prepared for subsequent painting, edge banding or other surface treatment processes.

The desktop may be made using jointing techniques to improve the overall strength and stability.

The wedding bar table legs are carved using precision lathe technology. After multiple processing procedures,

they are finely polished and carved into smooth curves and three-dimensional decorative patterns. Through

the high-speed rotating lathe tool, the wood is gradually cut into a classic European-style carved rotating

column, giving the table legs an elegant sense of lines and an exquisite three-dimensional shape. This

carving process retains the natural beauty of the wood and adds a sense of layering, making

the wedding bar table legs look more noble and elegant. The carved table legs will be finely polished to ensure

a smooth surface without burrs while maintaining the clarity and symmetry of each carved detail.

The four-legged support structure at the bottom is made using precise woodworking or mechanical cutting

techniques to ensure that each support leg is uniform in shape and standard in size, thereby improving

overall stability and load-bearing capacity. During the production process, high-quality wood is first selected

and then strictly measured and marked to ensure that the length, angle and thickness of the four support

legs are consistent. After production, the four-leg support structure needs to go through multiple grinding

processes to make its surface smooth and delicate, without protrusions or gaps at the joints, to ensure a

perfect fit during final installation and to integrate with the overall table leg design. The carefully crafted

four-leg support structure not only enhances the table’s load-bearing capacity but also ensures safety and

durability for long-term use.

During the surface treatment of the table, you first need to spray a layer of environmentally friendly

Water-based primer to improve the sealing of the wood and lay a good foundation for the subsequent coating

process. The environmentally friendly, water-based primer adopts a non-toxic, low-VOC (volatile organic compound)

formula, which can effectively penetrate the wood fibres and enhance the density of the wood, thereby

reducing cracking, expansion or deformation caused by changes in environmental humidity.

In addition, the primer can also form a protective film on the surface of the wood, effectively blocking the

intrusion of water while improving the adhesion of the topcoat, making the subsequent paint surface more

uniform and longer-lasting. During the spraying process, a professional spray gun needs to be used for

uniform coverage to ensure that all surfaces and corners can be fully coated, and after an appropriate drying

time, the primer is completely penetrated and cured. This not only enhances the durability and moisture

resistance of the tabletop but also effectively improves the smoothness and aesthetics of the final product,

ensuring that the overall quality of the table is more in line with high-end furniture standards.

After the primer is completely dry, light sanding is required to ensure an even coating and provide a smoother

surface for subsequent topcoat spraying. This step is usually done by hand or machine with fine-grit sandpaper

(such as 320# or higher) to gently remove tiny particles, uneven areas, and possible small bubbles on the

paint surface to improve the smoothness of the coating.

The sanding process needs to maintain moderate force to avoid damaging the sealing effect of the primer

and ensure that the wood surface is not damaged. After sanding, use a clean soft cloth or air gun to remove

surface dust to ensure that the paint surface is clean and free of impurities to provide better adhesion

for the next step of topcoat painting. This delicate treatment process not only enhances the durability of the

desktop paint layer but also makes the surface of the final product smoother and more delicate, presenting

a more refined and high-end texture.

During the spraying process, the spraying pressure, angle and movement speed of the spray gun must be

Strictly controlled to ensure uniform atomization of the paint and avoid problems such as sagging and paint marks

or color difference. Multiple thin spraying can enhance the smoothness of the paint surface, making it more

uniform and delicate, while avoiding excessive thickness of the paint layer that affects the drying effect.

In addition, after spraying, it is necessary to leave it in a dust-free and constant temperature environment to

allow the paint to flow evenly and solidify naturally to ensure that the final white paint surface is smooth and

translucent, delicate to the touch, and has good wear resistance and stain resistance, thereby improving the

overall quality and service life of the table.

To ensure that the paint effect of the tabletop is in the best condition, it may be necessary to spray

2-3 times in the end. After the first spraying, wait for the paint to dry fully and perform slight sanding to

remove the tiny particles or defects that may exist on the surface, to provide better adhesion for the

next layer of spraying. The second spraying can further enhance the uniformity of the colour, improve the

covering power of the paint on the surface, and make the color of the tabletop purer and more delicate. For

high-demand paint effects, a third spraying may be required to achieve perfect smoothness and

durability. After each layer of spraying, it needs to be left to stand at a constant temperature and dust-free

environment to allow the paint surface to level naturally and completely solidify to avoid problems such as

sagging, bubbles or color difference. After 2-3 times of fine spraying, the final painted surface will present a

delicate luster, smooth feel, and good anti-fouling, wear resistance and durability, making the table not only

beautiful and generous but also able to withstand long-term use without fading or damage.

To facilitate transportation and storage, tables are usually designed with detachable packaging to

minimize the transportation volume and reduce the risk of damage caused by collision or extrusion. This

packaging method usually packs the table legs separately from the tabletop and is equipped with corresponding

hardware accessories, which is convenient for users to assemble quickly after receiving it. During packaging

each component is protected with shockproof materials, such as foam pads, pearl cotton or bubble film,

to reduce scratches, bumps or deformation caused by shaking or collision during transportation.

In addition, all parts will be strictly classified, reasonably placed, and fixed with high-strength cartons or

wooden frames to ensure overall stability and not be easy to loosen or damage during long-distance transportation.

Using detachable packaging can not only improve transportation efficiency and reduce logistics costs

but also improve product safety, ensuring that the table remains intact when it reaches the customer.

At the same time, this packaging method is also convenient for storage and handling, making the table

suitable for different sales and use scenarios, meeting customers’ demand for high-quality furniture.

Reviews

There are no reviews yet.