Velvet Sofa Factory

This curved sofa uses smooth and elegant lines to outline a unique artistic shape. The overall shape is a soft curve, which can visually break the rigidity of the space and add a sense of dynamism and layering to the environment. The outer layer is made of a fine suede fabric with a smooth and delicate feel, good skin-friendliness and breathability, and is comfortable even after prolonged contact. The deep black tone is both fashionable and stable, and can blend perfectly with the surrounding environment, whether in a modern minimalist space or a luxurious high-end venue. The interior of the sofa is filled with high-density sponge, which has strong resilience and is not easy to collapse. It can maintain a full shape and a comfortable sitting feel for a long time. The backrest height is ergonomically designed to effectively support the waist and back, and reduce fatigue caused by long-term sitting. The segmented modular structure allows it to be freely combined, which is not only convenient for transportation and handling but also allows for flexible adjustment of the layout according to on-site needs. It is suitable for placement in straight rows, circular or irregular spaces.

Velvet Sofa Feature

- Elegant Styling – Curved design enhances the visual depth of any space.

- Multiple Color Options – Choose from a variety of fabric colors to easily match your style.

- Comfortable Experience – High-density foam padding provides long-lasting volume and support.

- Flexible Configuration – Modular construction adapts to various venue layouts.

- Premium Texture – Soft, durable suede fabric is fade-resistant and easy to care for.

Description

Our design team draws precise three-dimensional blueprints based on ergonomic principles and the spatial

layout requirements of the intended use scenario, ensuring the sofa strikes a balance between aesthetic

appeal and comfort.

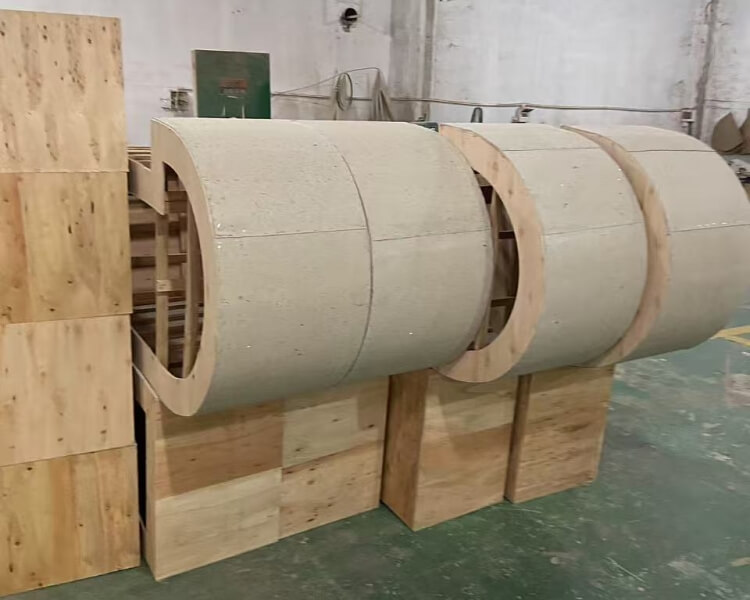

To achieve this unique curved shape, the factory imports the design drawings into CNC cutting equipment,

which, under precise computer control, cuts a skeleton mold from wood or high-strength composite panels.

Each arc is calibrated and polished to the millimetre level to ensure that the final structure perfectly matches

the designed curve, laying a solid foundation for subsequent frame assembly and fabric covering.

The production of the curved section is particularly critical, typically employing either steam bending or

segmented splicing. For steam bending, workers place the dried wood in a high-temperature steam box to

soften the internal fibres. The wood is then quickly placed into a specialised curved mould and securely secured

with specialised clamps. Once the wood has completely cooled and dried, a stable curvature is achieved.

For segmented splicing, the wood is cut into precisely angled segments, assembled one by one using

high-strength wood glue and invisible mortising. Then, clamps are used for a long period of pressing to ensure

secure joints and a natural curve. Regardless of the process, meticulous polishing ensures a smooth, burr-free

surface for the curved frame, providing an ideal foundation for subsequent cladding.

The neatly stacked, cut and polished layers of solid wood create a clear, sturdy wooden frame, laying a solid

foundation for subsequent filling and covering. This process not only ensures the sofa’s overall load-bearing

capacity and stability, effectively extending its lifespan, but also provides a smooth, even exterior for the

finished product, ensuring the sofa meets high standards in both comfort and aesthetics.

The main frame is constructed from rigorously screened, high-strength solid wood or high-quality multi-layer

boards, ensuring they are crack-free, insect-free, and have a controlled moisture content to prevent deformation

or cracking. Precision saws are used to cut the wood with precision, ensuring that the angles and lengths of

each component meet millimetre tolerances as specified in the design drawings.

Following cutting, the wood’s surface and edges are meticulously polished using a belt sander and

hand-sandpaper to remove burrs and sharp angles while ensuring a smooth surface, laying a solid foundation

for subsequent structural assembly and cladding.

High-density, high-resilience high-quality sponge is selected as the filling material to ensure good support

and shape stability after long-term use. According to the designed arc contour, the sponge is placed on a

large CNC cutting machine for precise cutting. Each piece strictly matches the curve of the frame to ensure

the fit of the subsequent covering.

The seat part adopts a multi-layer superimposed structure: the bottom layer is a supporting sponge with

higher hardness to provide solid support; the middle layer is a cushioning sponge with moderate elasticity

to enhance sitting comfort; the top layer is covered with soft and delicate high-elastic foam for a gentle touch.

A slightly lower density sponge is used for the backrest to better fit the curve of the human body and reduce

back pressure. All sponges will be chamfered after cutting to make the edge transition rounded, which not only

facilitates the smooth covering of the fabric, but also makes the lines of the finished product fuller and smoother.

Corners and curved areas require manual trimming of the sponge’s edges to perfectly match the curves of

the frame. Once all the adhesive is attached, workers check the sponge’s stability and flatness by pressing

and tapping it to ensure a full, smooth appearance when subsequently wrapped with fabric.

The cut fabric is evenly stretched and wrapped around the sponge and frame outer layer according to the

pre-marked positioning points and stitching directions. Workers will adjust the tension according to the stress

conditions of different parts, using a wrapping process with moderate tension and segmented fixing to ensure

a firm fit while preventing wrinkles or sagging in the fabric.

For curved corners, a multi-segment splicing and gradual stretching method is used to adjust the fabric little

by little to the optimal position, ensuring that the curve of the corner is natural and smooth without being

pulled or deformed. After the wrapping is completed, the seam position will be reviewed and slightly reshaped

to ensure that the overall appearance is full and rounded, and the lines are smoothly connected, highlighting

the sophistication and high-end feel of the sofa.

A soft, delicate suede fabric with a smooth touch is selected as the outer covering material. Before entering

the production process, it undergoes an anti-fading treatment to ensure that the color remains rich after

long-term use, an anti-static treatment to prevent dust adhesion, and an anti-pilling treatment to maintain

a smooth and clean surface.

When cutting, the sofa is cut into blocks according to the curved modular structure, and the layout is strictly

unified according to the natural direction of the velvet to prevent color differences or inconsistent reflections

in the finished product. Each piece is precisely spliced by experienced sewing workers operating industrial

sewing machines, with even stitches and consistent stitch lengths. The seams are reinforced to not only

enhance strength but also keep the lines straight during subsequent stretching and wrapping, ultimately

presenting an appearance that is both durable and refined and smooth.

The sturdy, round plastic feet provide a secure support for the sofa and protect the floor from scratches.

On the right side is a polished, exquisitely crafted metal lock mechanism that secures the fabric underneath

and facilitates future removal or maintenance. This thoughtful design not only enhances the sofa’s durability

but also facilitates daily cleaning and maintenance.

After assembly, workers use a special suede brush to smooth the fabric texture, ensuring a smooth touch

and uniform color. Quality inspectors perform stability tests, fabric flatness checks, seam tightness checks,

and appearance checks to ensure every sofa leaves the factory flawless.

-

Please click on the link below to browse more of our sofa products:

More Sofa Products

Reviews

There are no reviews yet.