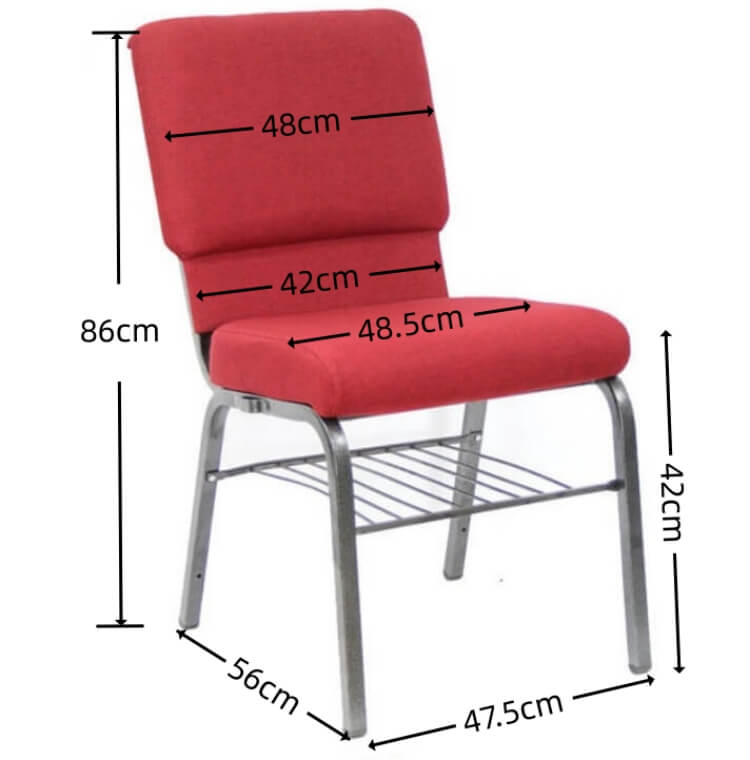

Church Chairs Manufacturers

Qingdao BlossomFurnishings Limited has workshops for producing home, restaurant, catering, event, wedding, party and hotel furniture, and has rich experience in large-scale production of church chairs. Church chairs are a key element in creating a comfortable and inviting worship environment. Designed with the needs of the congregation in mind, these chairs offer ample seating while maintaining an elegant and stylish design. Crafted from high-quality materials, they are built to last. Their ergonomic design and softly padded seats provide optimal support and comfort during extended worship services or events. They are easily stackable and store for versatility and space-saving convenience.

Church Chairs Feature

- Durable commercial-grade fabric with CAL 117 flame-retardant foam

- 4-inch thick seat with 5-inch thick waterfall relief rim

- Floor protection pads, plastic rocker slides to protect floors from damage

- 800 lbs load capacity

Description

Durable Frame

This church chair features a powder-coated steel frame constructed from 16-gauge, 13/16-inch square tubing,

providing a sturdy and durable frame that withstands long-term use. The seat and backrest are securely

fastened to the frame with T-nuts, which are more stable than traditional wood screws and less likely to loosen,

further enhancing the overall structural strength and durability.

Ganged Design

The church chairs feature built-in ganged brackets, allowing multiple chairs to be easily connected, ensuring

a uniform arrangement for meetings, ceremonies, or banquets. This design not only saves space but also

effectively prevents chairs from moving around, enhancing safety and overall aesthetics.

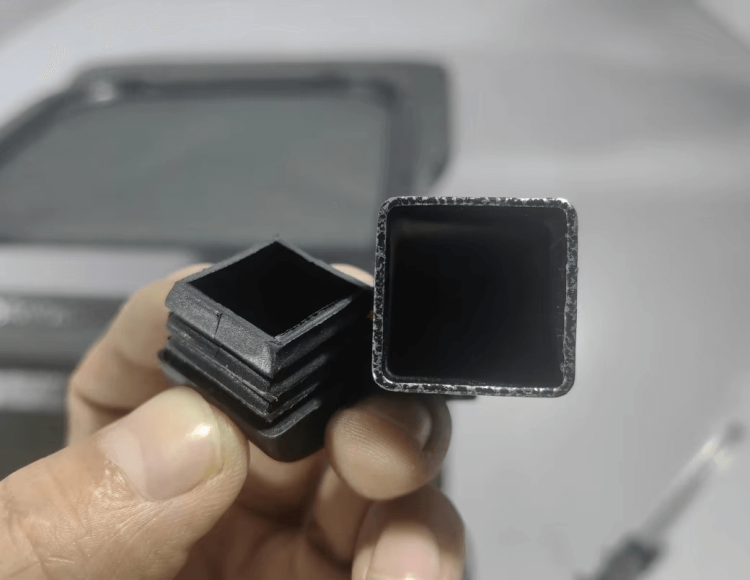

Protective Feet

The church chairs feature a sturdy 16-gauge steel frame with anti-collision pads to protect them from

scratches when stacked. Curved plastic feet ensure smooth movement, making it easy to move the chairs

without scratching or damaging floors.

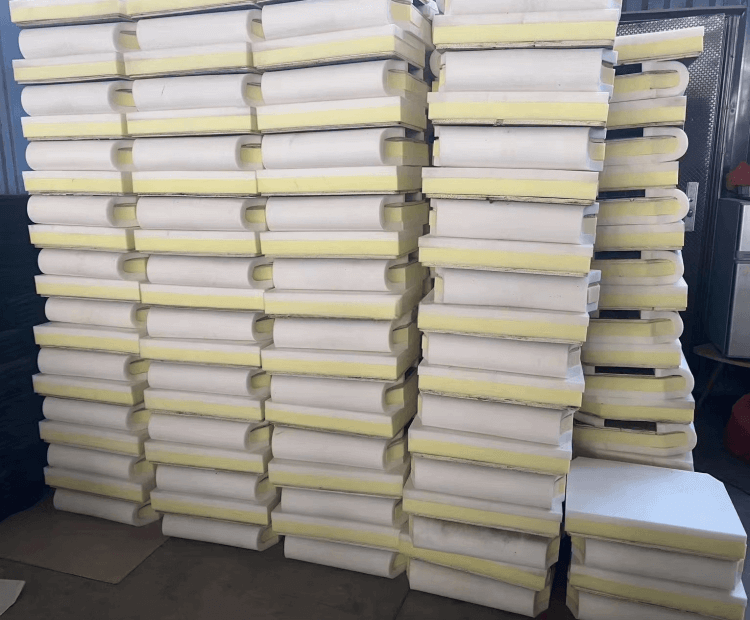

Comfortable Seating

Both the back and seat are thickly padded, with the seat boasting a depth of 4 inches, providing excellent

support and comfort. The exterior is covered in durable fabric for a refined feel and durability. The ergonomically

designed waterfall edge of the seat reduces leg pressure, ensuring comfort even during extended periods.

Raw Material Preparation

The production process begins with rigorous raw material selection. We use 16-gauge square steel tubing

for the church chair frame. Each piece of steel undergoes individual inspection to ensure uniform wall

thickness and a surface free of rust, dents, and cracks. This high-quality steel not only provides a stable

foundation for subsequent cutting and welding, but also ensures the strength and durability of the finished

chair frame, laying a solid foundation for long-term, frequent use.

Welding and Forming

During the welding process, workers position and secure the cut pipes according to the design drawings,

using high-precision welding equipment to connect each component of the chair frame securely. The

temperature and weld point locations are strictly controlled during the welding process to ensure full,

even joints, free of pores or cracks. Multiple reinforcement welds are performed at all critical stress points

to ensure the stability and load-bearing capacity of the overall frame. After welding, the chair frame takes

shape, creating a clear outline and laying a solid foundation for subsequent polishing and surface treatment.

Grinding and Polishing

After welding, the church chair frame enters the grinding process. Using specialized tools like angle grinders

and belt sanders, workers perform multiple rounds of grinding on all welds, seams, and corners, thoroughly

removing burrs, weld scars, and excess slag to ensure a smooth surface. The curved backrest and joints are

meticulously polished to eliminate scratches and unevenness. Polishing then completes the process, creating

a soft and uniform metal surface. This provides an ideal adhesion base for subsequent painting or electroplating

processes, while also enhancing the overall aesthetic and quality of the exterior.

Surface Spraying

Before spraying, the chair frame undergoes rigorous pre-treatment, including degreasing, rust removal,

and phosphating. This thoroughly removes residual oil, oxide layers, and impurities from the surface,

ensuring secure coating adhesion.

Next, the church chair frame undergoes spraying, where an electrostatic spray gun evenly applies an

environmentally friendly powder to the surface. The powder cures at high temperatures, forming a dense,

smooth protective coating that is not only wear-resistant, scratch-resistant, and rust-resistant, but also

effectively resists the wear and tear of daily use and the erosion of humid environments. The spraying process

also offers a variety of color options, giving the chair a stylish and elegant appearance, perfect for weddings,

banquets, and other occasions.

Covering and Installation

After the sponge and outer fabric are prepared, workers secure the sewn fabric and shaped sponge to the

seat and backrest frames. During the covering process, the fabric is carefully stretched and adjusted to ensure

a tight, flat surface without wrinkles or looseness. The edges are reinforced with industrial staples or specialised

clips to ensure a tight fit between the fabric and sponge, securing them securely to the chair frame. Corners

and curves are manually shaped to maintain a natural, smooth curve and enhance the overall aesthetic.

After covering, the seat and backrest are securely connected to the chair frame with screws or welds, forming

a stable, integrated structure that provides users with a comfortable and stable seating experience.

Complete Packaging

Complete packing is used for finished chairs that require no further assembly. Each chair is first covered with

a dustproof cloth, and key areas such as the backrest, armrests, and legs are protected with corner guards or

foam padding to prevent bumps and scratches during transportation. The chairs are then stacked according

to the designed arrangement, separated by soft plugs or plastic film to maintain stability and prevent friction

damage. Thick protective film is then wrapped around the chairs, and strapping tape is used for reinforcement.

Finally, the entire set of chairs is placed on a custom wooden pallet for easy forklift loading and unloading,

and container loading. This method not only significantly improves transportation efficiency but also ensures

that the chairs arrive safely and intact.

Related products

-

Solid Wood Cross Back Dining Chairs Wholesale

Rated 5.00 out of 5

Reviews

There are no reviews yet.