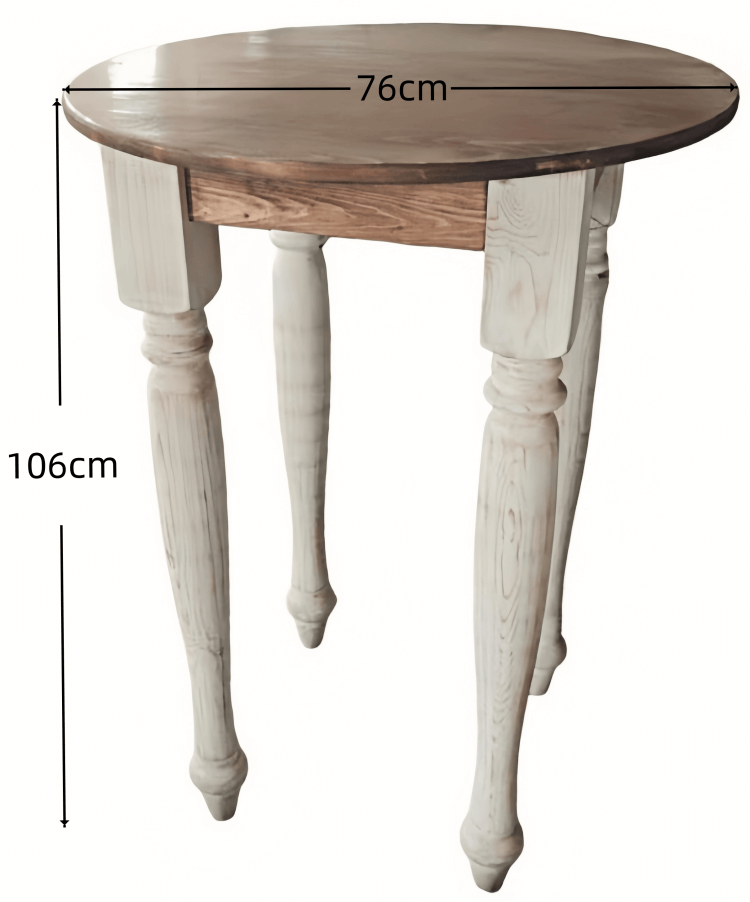

Wooden Bistro Bar Table

This solid wood pub bar table is crafted from high-quality solid wood, featuring a sturdy and stable structure that combines practicality with the classic pub style aesthetic. The tabletop is made from multiple pieces of solid wood joined together, and the base is reinforced with a sturdy frame structure, effectively enhancing overall load-bearing capacity and long-term stability. The table legs are processed using traditional woodturning techniques, resulting in smooth and elegant lines that give the bar table a strong pub and vintage commercial space atmosphere while maintaining robust support.

The surface undergoes multiple stages of fine sanding and eco-friendly coating treatment, preserving the natural wood grain texture, providing a smooth touch, and ensuring durability and ease of cleaning and maintenance. This commercial bar table is suitable for bars, pubs, restaurants, cafes, and various events and commercial projects, meeting the demands of frequent use and long-term placement. It is an ideal choice for commercial spaces, offering both functionality and decorative appeal.

Wooden Bistro Bar Table Feature

- Solid wood structure, stable and durable.

- Multiple points of fixation ensure a sturdy structure.

- Smooth surface treatment, easy to clean and maintain.

- High Stability for Heavy-Duty Commercial Use

Description

This solid wood bar table features a sturdy overall structure, a thick and substantial tabletop, and rounded

edges for a natural and smooth feel. The design enhances the overall visual appeal. The wood grain on the

tabletop is clear and natural, preserving the texture and colour of the solid wood, which gives the table an

authentic, warm, and high-quality appearance.

The bar table legs feature a classic turned wood design, with full and layered lines that create a stable yet

elegant appearance, combining both decorative appeal and structural support

As a solid wood bar table, the legs are securely connected to the tabletop, creating a harmonious structure.

The horizontal support at the base further enhances overall stability, preventing the table from wobbling

during use. This makes it ideal for multiple people to lean on or place drinks, and it is perfectly suited for use

as a high-top table in bars, restaurants, and wedding receptions.

How a Solid Wood Bistro Bar Table Is Made?

Tabletop panel joining and reinforcement structure

This solid wood bar table features a tabletop constructed from multiple pieces of high-quality wood

solid wood planks. Before assembly, workers carefully select and match each plank based on thickness,

grain direction, and moisture content to ensure a stable structure and naturally uniform wood grain. During

the assembly process, workers precisely control the fit and gap size between the planks, maintaining excellent

flatness and effectively reducing the risk of cracking and warping in the solid wood tabletop during long-term use.

To enhance the stability and load-bearing capacity of our commercial bar tables in high-frequency use scenarios,

we have added a solid wood reinforcement frame structure to the underside of the tabletop. The table’s

reinforcement frame utilizes a design that combines horizontal and vertical supports, ensuring more even

distribution of weight and significantly increasing the overall strength of the tabletop. This structure effectively

prevents sagging, deformation, or loosening of the bar table under prolonged heavy loads or when multiple

people lean on it, extending the lifespan of the entire solid wood bar table.

Table leg manufacturing and shaping processes

The legs of our pub tables are meticulously crafted using traditional woodturning techniques. Our skilled

craftsmen select high-quality solid wood with a stable structure and uniform density. These wood pieces are

gradually shaped through a rotational cutting process. The entire manufacturing process involves multiple

stages of turning, shaping, and proportion adjustments, resulting in table legs with smooth, flowing lines and

natural transitions. This not only enhances the overall aesthetics of the table but also effectively strengthens

the vertical load-bearing capacity of the legs, meeting the demands of long-term commercial use.

After being manufactured and shaped, the table legs undergo multiple rounds of meticulous sanding.

Workers progressively move from coarse to fine sanding, ensuring the table legs have a smooth, even surface

and a pleasant feel, effectively reducing splinters and rough edges. The traditional turned wood structure

not only enhances the structural strength of the table legs but also creates a classic, sturdy tavern-style

appearance for the entire solid wood pub table, making it suitable for bars, pubs, restaurants, and commercial

spaces.

Bottom structure processing and groove positioning

During the fabrication of the base structure for our pub bar tables, all solid wood reinforcement strips are

precisely cut according to the design drawings, with strict control over length, width, and thickness dimensions

to ensure uniform specifications and structural stability of all components. During the manufacturing process,

based on the stress requirements of the base structure, the reinforcement strips are pre-grooved and positioned,

allowing for accurate alignment of all connecting parts before assembly.

The grooving process for our tables utilizes standardized manufacturing methods, with the depth, width,

and spacing of the grooves precisely calculated. This ensures a tight and secure fit between the reinforcing

wooden strips and the tabletop and legs. Through a well-designed groove pattern, the workers create a stable

overall framework with both horizontal and vertical support structures. This effectively distributes the

weight-bearing pressure on the tabletop, significantly improving the stability and durability of the commercial

bar tables during long-term use.

The reinforcing wooden strips on our tables are made of solid wood, with ample thickness and neatly cut

edges that fit tightly against the tabletop. Each reinforcing strip is positioned using pre-drilled holes and then

secured with metal bolts, ensuring clear load distribution and a robust structure at the connection points.

The bolts are evenly distributed, guaranteeing both durability and ease of disassembly or maintenance,

making them suitable for the high-frequency use and bulk transportation requirements of commercial bar tables.

Tabletop and Table Leg Assembly and Fixing

The tabletop and legs are connected using a reinforced structure at the bottom. Before assembly, workers

precisely calibrate the pre-drilled mounting holes on the underside of the tabletop and the connection points

on the legs, ensuring that all load-bearing points are accurately aligned and the installation angles are correct,

thus laying the foundation for overall structural stability.

During installation, the workers connected the table legs to the reinforcing frame using a multi-point fixing

method. All bolts and fasteners were tightened to the standard torque, ensuring a secure and stable connection

that is resistant to loosening. This well-designed load-bearing structure evenly distributes the weight of the

tabletop and external pressure to the table legs and base frame, effectively enhancing the stability of the

commercial bar table during daily use and reducing the risk of wobbling or tilting.

After the workers finish sanding, they clean the wood surface to ensure there is no dust residue before evenly

applying an environmentally friendly coating. This coating penetrates the wood grain while preserving the

natural wood grain and original texture of the solid wood, giving the solid wood pub table a more natural and

layered appearance. With the protection of the coating, the tabletop has excellent wear resistance, stain resistance,

and daily protection, effectively resisting minor scratches, water stains, and dirt from everyday use.

Finished Product Inspection and Shipping Preparation

Quality control personnel will conduct a comprehensive inspection of the bar table, focusing primarily on the

sturdiness of the connection between the tabletop and the legs, ensuring that all fixing points are stable and

free from any loosening issues. At the same time, workers will verify the overall flatness and levelness of the

entire table, ensuring that it remains stable and does not wobble under normal use, meeting the standards

for long-term commercial use of bar tables.

In terms of appearance, the focus is on inspecting the surface finish of the tabletop, legs, and corners,

ensuring that the wood grain is natural, the coating is even, and there are no obvious scratches, colour differences,

or manufacturing defects. For bulk orders, consistency checks are also performed to ensure that different

batches of solid wood pub tables maintain uniformity in size, structure, and appearance, meeting the procurement

requirements of international customers for standardised products.

Reviews

There are no reviews yet.