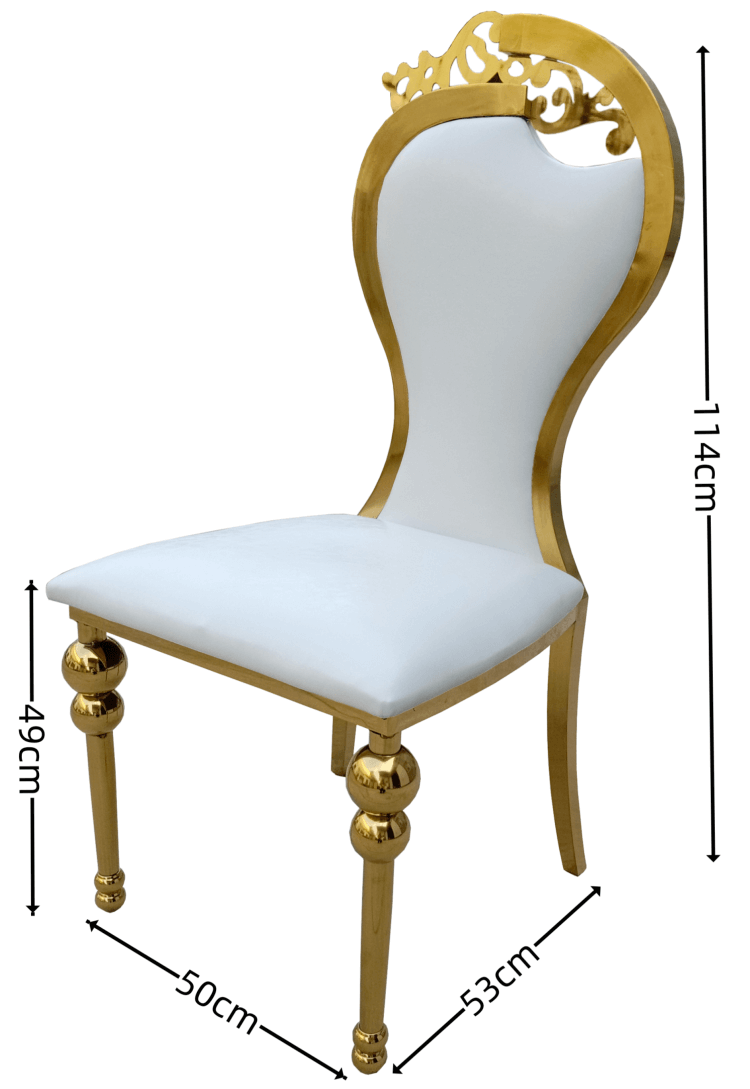

Classical Golden Elegant Chair

Enhance the visual appeal of your interior with this luxurious dining chair. This side chair features a slim backrest and curved convertible legs, perfectly matched to give it a vintage appeal. Seat upholstered in white PU leather, padded with elastic foam for absolute comfort. It’s made from high-grade stainless steel with a gold finish, giving it a timeless luxurious look while ensuring a durable solution and sturdy support for frequent use. Bring this dining chair home and liven up your space! At the same time, it is perfect for brides and grooms on any wedding occasion. The eye-catching stainless steel frame is sure to make the bride, groom, or guest of honor the center of attention as they sit comfortably in the chair.

Classical Golden Elegant Chair Feature

- Weight capacity: 331 lbs/150 kg-551 lbs/250 kg

- Fully welded construction. The screws or hinges won’t loosen over time, ensuring years of worry-free product.

- The seat cushion is filled with a high recovery sponge, which is full, thick, soft, and comfortable.

- Clear floor glides on the bottom of the legs will keep your hard surface floors scratch-free while moving.

- The frame is scratch-resistant, impact-resistant, durable, and chemically treated to prevent rust.

Description

This luxurious yet supremely comfortable leather dining chair is the ideal companion to a round floral

or oval dining table. Designed with attention to detail, the padded seat and contoured backrest guarantee

an all-around comfortable ride. This chair is a luxurious addition to every dining space, injecting a sense

of elegance and comfort into the dining venue.

First, workers prepare various stainless steel parts, which are usually pre-machined on CNC machines. The

key goal of this step is to ensure part accuracy and consistency so that a high-quality finished product can

be achieved during subsequent welding and assembly stages.

These pre-machined parts include various parts of the chair, such as legs, beams, seats, and back supports.

Each part is precisely designed and calculated to meet the requirements of different chair models. The use

of CNC machines allows a high degree of automation and accuracy in the preparation process.

At this stage, cutting, drilling, and other process steps are indispensable. The cutting process can be carried

out through advanced technologies such as laser cutting or plasma cutting, ensuring that the dimensions of

the stainless steel parts are precise and the cut edges are flat. Drilling is done to create connection points

and assembly holes, ensuring that the individual parts can be easily joined together during the subsequent

assembly stages. The execution of these process steps requires strict quality control to ensure that each part

meets design requirements.

Before starting welding, our craftsmen first ensure that the surface of each part is completely clean,

eliminating any impurities that may affect the quality of the weld. Welders use precision and reliable welding

equipment, usually arc welding or TIG welding, to delicately join stainless steel parts together. This requires

a high level of skill and every movement requires exquisite technique. The art of welding is to ensure uniformity

of the weld, making it both strong and beautiful to ensure that the chair is structurally sound and durable.

The chair is electroplated. This step improves corrosion resistance and durability by creating a uniform

metallic coating on the chair’s surface. Electroplating can not only increase the surface hardness of the chair

but also make it have better wear resistance and extend its service life. It’s like putting a layer of solid armor

on the chair, protecting it from outside elements.

The worker will place the chair back cushion in the corresponding position of the chair according to the

design requirements. Install screws, nuts, or other connectors accurately to ensure that the back cushion

can be securely fixed to the chair.

During the installation process, craftsmen pay special attention to detail. They make sure every connection

point is strong and secure to prevent the chair from wobbling or becoming unstable during daily use. This

also includes adjusting the position of the backrest cushion so that it is both design-friendly and ergonomically

correct to provide optimal sitting support.

Once the chair back cushion is installed, craftsmen may perform final inspections to ensure that the chair’s

appearance and comfort meet established standards. This stage is a critical part of the entire manufacturing

process, as the final quality and user experience of the chair heavily depend on the accurate fit and proper

adjustment of each component.

Before being packaged, gold stainless steel dining chairs typically undergo a final cleaning and inspection

to ensure there are no stains, scratches, or other defects on the surface. This helps in providing users with

a perfect product.

The worker holds the stretch film and starts at one end of the chair, cleverly wrapping it tightly. The

application of stretch film begins at the base or seat of the chair to ensure adequate coverage of the surface.

During the wrapping process, workers evenly go around the contours of the chair, maintaining tension on

the stretch film to ensure tight and even coverage. This stretch film acts as a protective barrier, effectively

protecting the chair from scratches and contamination during transportation and storage.

Workers put a protective plastic cover on the backrest of the chair. We customize the cartons for the chairs

according to the size of the chairs. Cartons provide additional physical protection, mitigating shock and

vibration during handling and transportation.

Reviews

There are no reviews yet.