Metal Bar Dining Chair Factory

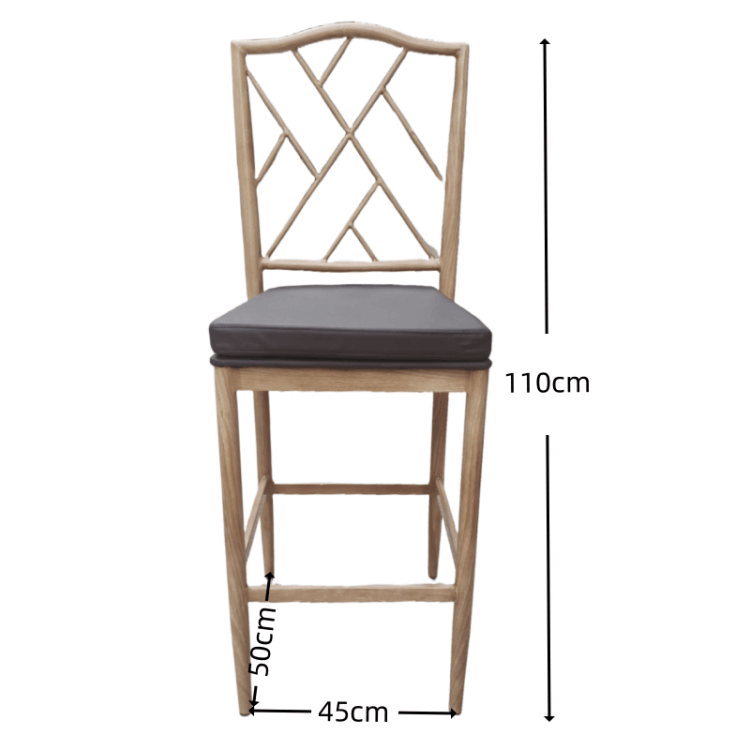

QINGDAO Blossom Furnishings Limited is a professional furniture factory specialising in manufacturing commercial-grade dining and event chairs. This metal bar dining chair is made of high-quality aluminium alloy, which is lightweight, durable, and resistant to rust and corrosion — ideal for high-traffic commercial use. The backrest features a unique geometric cross-line design, adding a modern and stylish touch while maintaining structural stability. The seat is equipped with a high-density cushion covered in wear-resistant leather (PU, PVC, or tech fabric optional), offering comfort and easy maintenance. Reinforced crossbars and footrests enhance both support and long-term seating comfort. The surface is finished with eco-friendly powder coating, available in multiple colour options to match different venue styles. Suitable for weddings, high-end restaurants, bars, and event venues.

Metal Bar Dining Chair Feature

- High-strength aluminium alloy frame, rust-proof and anti-corrosion

- Geometric chair back, unique design

- Soft leather seat, comfortable and easy to clean

- Reinforced footrest structure, stable and durable

- Multiple colours available, support customisation

- Suitable for weddings, banquets, restaurants, bars and other scenes

Description

How to produce Metal Bar Dining Chairs?

-

The Quality of the Aluminium Used in the Bar Dining Chair

The aluminium tube materials are strictly selected and certified, with a smooth surface, uniform wall thickness,

good mechanical processing performance, and suitable for subsequent cutting, bending, welding, spraying

and other process links. This type of aluminium material not only ensures the overall lightness of the chair,

but also has the characteristics of anti-oxidation, anti-corrosion, and is not easy to crack and deform, making

it an ideal choice for outdoor and high-frequency use environments.

-

How to Cut Aluminium Tubes Accurately?

Using advanced CNC cutting machines, we input product design drawings through computer programs to

automatically perform cutting operations and achieve efficient and high-precision processing.

All aluminium tubes are precisely cut one-to-one according to the 3d structural drawings, and the error is

strictly controlled within **±0.5mm** to ensure that each component fits closely during the subsequent

welding and assembly process.

-

Precision Tube Bending

Workers use pipe-bending machines to shape aluminium tubes, accurately bending them according to the

design of the chair to form an ergonomic chair leg shape. The bent aluminium tubes need to be checked

one by one to ensure that the curve is natural, without wrinkles or deformation.

-

How to install the chair frame accurately?

Workers place the metal pipes processed through the pipe-bending process one by one into the customised

welding fixture. The fixture is specially designed according to the structure of the chair, and can accurately fix

the position and angle of each pipe to ensure that all parts are accurately aligned before welding. After the

positioning is completed, the workers use professional welding machines to perform multi-point welding,

first pre-welding the key connection points to ensure that the overall shape is fixed, and then full welding is

performed to enhance the structural strength. Throughout the process, each welding point must be kept

even and firm to avoid false welding or offset, to ensure that the chair frame will not loosen, deform or

crack during long-term use, and to lay a solid foundation for subsequent grinding, spraying and other processes.

-

Fine Grinding After Welding

After welding is completed, workers will finely grind and polish each welding point and all exposed aluminium

surfaces. Using efficient grinding equipment, all welding slag and burrs left over from the welding process are

removed to ensure that each joint is smooth and flat. The meticulous surface treatment not only improves the

feel of the product but also creates ideal underlying conditions for subsequent electrostatic spraying – the

coating can be evenly attached to the aluminium, improving the overall aesthetics and anti-corrosion effect.

For aluminium chair frames, the refinement of this process directly determines the durability and weather

resistance of the final product, and is a key step in ensuring quality.

Chair welding is the core of the entire production process. Workers put the bent aluminium tubes into a

special fixture according to the design size and position them accurately to ensure that each connection

point has an accurate angle and a stable position. Then, argon arc welding is used to connect the components

firmly to form a complete chair frame.

During the welding process, the temperature and welding point quality are strictly controlled to ensure that

the weld is full and smooth, without any false welds or leaks. After welding, the chair frame structure is strong

and not easy to deform. It can withstand long-term repeated use and meet the high requirements of strength

and durability in commercial activities.

After the chair frame is welded, workers will check each chair one by one to ensure that the structure is firm

and the size is consistent. The picture shows the aluminium banquet chairs arranged in a row after the

welding process. It can be seen that the overall frame has been formed, with a regular shape and smooth

lines. Each welding point is strictly controlled to ensure that there is no false welding and no misalignment.

This stage mainly involves confirming the welding quality of the chairs and testing their stability after the

initial assembly, laying a solid foundation for subsequent surface treatments such as grinding, polishing,

and spraying. The neatly arranged chair frames not only reflect the standardised production process, but also

reflect the factory’s high attention to product consistency and quality.

After the chair frame is welded and inspected, the next step is grinding and spraying. Workers use special

equipment to carefully grind all welding parts and the entire aluminium tube surface to remove welding slag,

burrs and surface unevenness, ensuring that the chair frame is smooth to the touch and has no sharp edges,

and providing a good adhesion foundation for spraying.

-

Support Customised Services

We support customised production according to the drawings or design plans customers provide.

Whether it is size, structure or style details, it can be flexibly adjusted to meet the personalised needs of

different scenarios and markets. This chair was tailor-made for a customer in Philadelphia, USA, combining

their specific design requirements and functional uses. It not only reflects the brand characteristics of the

customer, but also demonstrates our professional ability and production strength in non-standard customisation.

-

Can it be paired with a cushion?

Wear-resistant leather: The surface is made of highly wear-resistant, environmentally friendly leather

(PU, PVC or technology cloth can be selected according to needs). The leather surface is soft and delicate,

with good scratch resistance, stain resistance and easy cleaning properties. Daily care only requires wiping

with a damp cloth. It is suitable for high-frequency use scenarios such as wedding banquets, restaurants or

commercial places.

High-density rebound foam: Polyurethane foam with a density of 40d or above is used, which has good

support and resilience. It can quickly return to its original shape after sitting for a long time and is not easy

to collapse or deform. The foam is cut precisely, and the size is regular to ensure that the cushion is full and

beautiful as a whole.

Processing: The foam and leather are precisely covered by hand, the four corners are flat, and the stitching is

neat and firm, and wrinkles or looseness are avoided, which not only ensures a beautiful appearance, but also

increases the service life of the product.

The finely polished aluminium chair frame will be sent to the dust-free spraying line for electrostatic powder

spraying. First, each chair frame needs to be purged and degreased with high-pressure gas to completely

remove the dust, oil stains and grinding particles remaining on the surface to ensure the best adhesion of

the coating.

The spraying uses environmentally friendly, high-quality polyester powder, and the powder is evenly adsorbed

on the surface of the aluminium tube through an electrostatic spray gun. Due to the strong conductivity of

aluminium itself, the powder can be firmly wrapped in every corner and welded under the action of static

electricity to ensure no leakage and no accumulation.

-

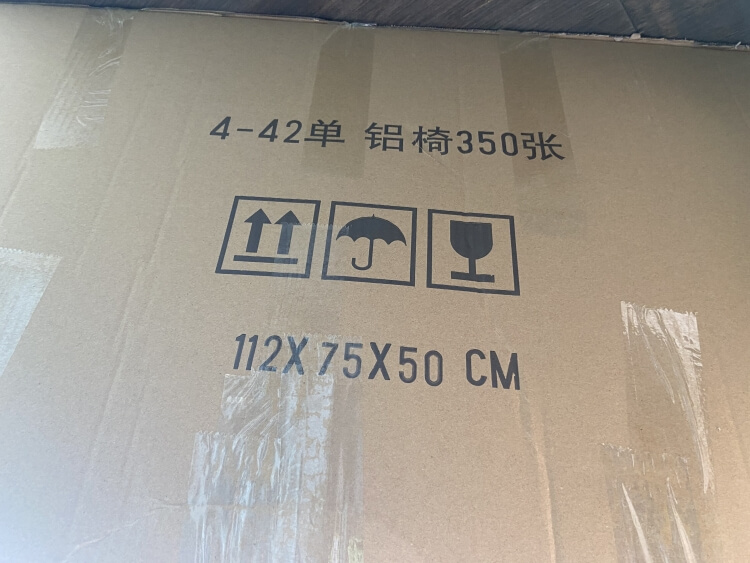

How are the Metal Bar Dining Chairs Packaged?

After the aluminium chairs have been sprayed and passed the appearance and structure inspection, they will

enter the final packaging process. First, the surface of each chair will be fully wrapped with anti-scratch foam

paper or pearl cotton, especially the corners of the chair back, leg joints and other easily collided parts,

which will be affixed with cushioning protection pads to prevent scratches or bumps during transportation.

Then, workers will pack the chairs into special customised cartons according to their sizes. The cartons are

made of a five-layer or seven-layer thickened corrugated structure, which has good compression and impact

resistance, ensuring that the products are effectively protected from deformation and damage during

long-distance transportation, or stacking and storage.

Each box is usually equipped with positioning materials or foam spacers to prevent friction between multiple

chairs. Some models are also packaged separately, with the seat and frame packaged separately, and detailed

installation instructions and required accessories are attached, so that customers can assemble and use them quickly.

Reviews

There are no reviews yet.