Modern Tripod Round Coffee Table Manufacturer

Qingdao Blossom Furnishings Limited is a professional wholesale supplier specializing in wedding chairs and banquet tables, integrating R&D, production, and sales. The company owns its own modern factory. This three-legged round coffee table features a simple structure and stable support design at its core, combining metal legs with a solid wood tabletop to present a balance between natural and modern styles. The legs are treated with electrostatic spraying, resulting in a smooth, wear-resistant surface that is not prone to paint peeling. The tabletop has undergone multiple sanding and sealing processes, ensuring a comfortable touch and long-lasting color. Suitable for various occasions such as weddings, parties, restaurants, and outdoor events, this multi-functional table combines practicality and aesthetics.

Modern Tripod Round Coffee Table Feature

- High-strength metal legs with even and wear-resistant paint coating.

- Lightweight and easy to move, suitable for various activities and scenarios.

- Customizable size, color, and tabletop material.

- Sturdy three-legged structure, evenly distributes force, and is not easily shaken.

Description

This three-legged coffee table comes in a variety of sophisticated colors and is available in two sizes:

80×110cm and 80×76cm, catering to different spatial layout needs. It can be easily placed in spacious

areas or compact corners. With a range of color options including warm wood tones, Morandi pink,

pure white, and all-black, it can be freely combined to create a more harmonious and sophisticated

atmosphere suitable for homes, cafes, and commercial spaces.

Coffee Table Colour

Our coffee tables come in various colors, including walnut wood tabletop with black legs, Morandi pink tabletop

with natural wood legs, pure white tabletop with white legs, natural wood tabletop with white legs, and all-black

(black tabletop with black legs). We can also customize colors according to customer needs.

How are coffee tabletops manufactured?

Each piece of wood is carefully selected and inspected before entering production to ensure natural grain

and stable structure. To make the tabletop more durable for daily use, we first dry the wood to gradually

remove excess moisture, thus minimizing the risk of warping or cracking in the future.

We then feed the wood into a CNC cutting machine for cutting. During the cutting process, the machine

precisely cuts the wood into standard circular tabletops according to preset dimensions and curvature,

ensuring that each tabletop is the same size and has smooth edges, providing a stable foundation for

subsequent processing.

To ensure rounded edges and precise dimensions, workers chamfer the cut tabletops and perform an initial

rough sanding, using coarse sandpaper to quickly smooth out cutting marks and create a flat surface. Then,

finer sandpaper is used for further sanding to make the tabletop surface even smoother.

After sanding, the desktop surface will be sealed and treated with moisture-proofing to enhance its durability.

Next comes the spraying process, where environmentally friendly paint is used for multiple even sprayings.

Each layer needs to be air-dried or oven-dried after spraying to ensure that the paint adheres firmly and has

a rich color.

We sand the surface between each coat of paint to achieve a smoother finish. After sealing, a strong

protective layer forms on the desktop. This protective coating not only gives the desktop a soft, glossy

finish but also effectively enhances its water resistance, scratch resistance, and stain resistance,

significantly extending its lifespan.

What are the steps involved in making coffee table legs?

The coffee table legs are made of high-strength metal (such as carbon steel or high-quality iron), and undergo

strict screening from the raw material stage to ensure uniform metal thickness and strength standards.

After the raw materials enter the factory, they are first cut and straightened to ensure that each metal tube

is straight and that slight bending will not affect the structural stability.

Bending and Forming

Based on the table’s three-legged structure, the metal tubing is fed into a bending machine and precisely

bent at a set angle. The bending process requires ensuring consistent left and right angles to guarantee

balanced force distribution and overall stability of the table legs after placement, preventing wobbling.

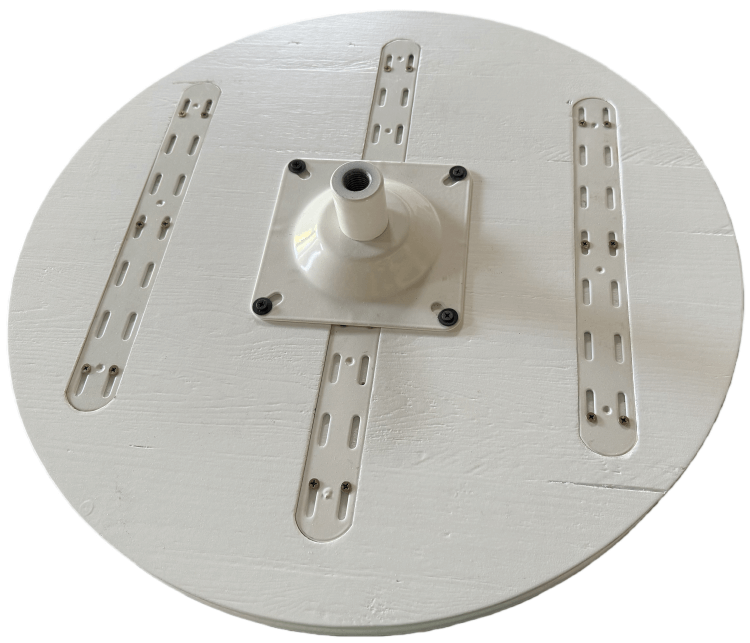

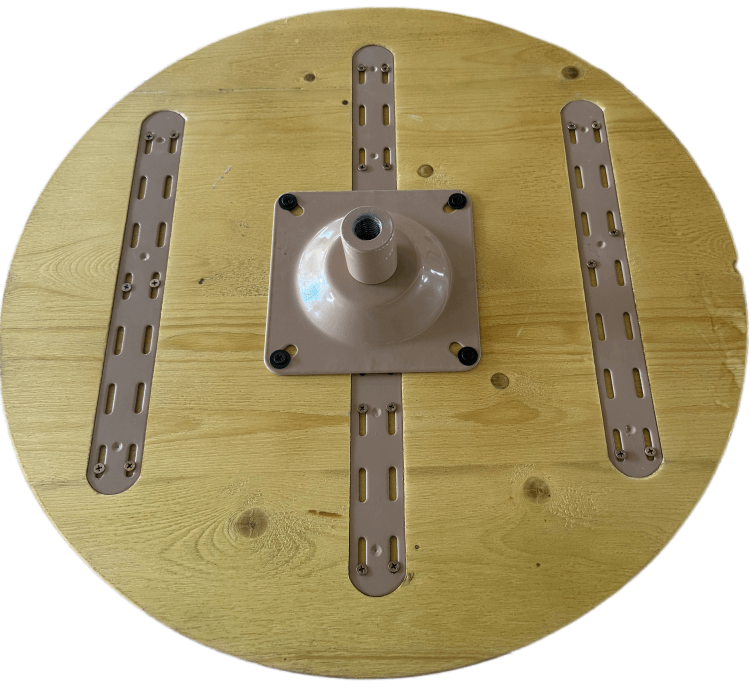

A thickened metal support plate is installed at the top of the table legs. It is precision molded and stamped,

resulting in a high degree of flatness and a more stable structure. Standardized screw holes are pre-drilled

at the four corners of the support plate, with precise and consistent hole spacing to ensure seamless

alignment when installing the tabletop.

The table legs and the load-bearing plate are connected by a screw-locking structure. Each table leg has a

precisely pre-drilled hole at the top, and the load-bearing plate also has screw positions set according to the

standard hole spacing. During installation, the worker will align the load-bearing plate with the joint at the top

of the table leg and tighten it point by point with thickened self-tapping screws to ensure a tight fit between the two.

This method is easier for later transportation and maintenance than traditional welding, while ensuring

that the stability of the joint is not reduced. Multi-point screw locking makes the force distribution more

even, and the combination of the table legs and the load-bearing plate is more secure. It is not easy to

loosen or wobble during long-term use, effectively improving the durability and load-bearing capacity of

the entire coffee table.

The weight testing process for the tall and short coffee table legs: Each table leg was placed on an electronic

scale and measured individually. The measured weight of the tall table leg was 3.67 kg, and the measured

weight of the short table leg was 2.548 kg.

Before leaving the factory, each coffee table undergoes a rigorous final quality inspection process. Quality

inspectors first check the painted surface to ensure uniform color, no paint runs, and no scratches. Next,

they check the flatness of the tabletop, confirming a smooth surface without warping or paint defects.

Then, they check the stability of the coffee table legs, ensuring all three legs are at the same height and do

not wobble when placed on a flat surface. Finally, a comprehensive inspection of the entire table’s appearance

is conducted to ensure there are no dents, dirt, deformation, or other defects. Each inspection step is strictly

controlled to guarantee the highest standards in both visual appeal and user experience.

How is the coffee table packaged?

The coffee bar table is packaged separately for the tabletop and legs, making it easier to stack and effectively

saving display space. All components are layered with materials such as pearl cotton, shock-absorbing foam,

and soft corner protectors to provide comprehensive protection for the tabletop’s paint and metal legs,

preventing scratches, wear, or collisions during transportation.

The tabletop can be placed upright or flat, with anti-slip pads and soft partitions between it. The table legs

are individually covered and then neatly placed upright, arranged in a “trapezoidal stacking” manner, so that

each table leg interlocks with the others, improving overall stability.

Modern Tripod Round Coffee Table – Installation Video

This installation video demonstrates how to assemble our Modern Tripod Round Coffee Table quickly and correctly.

The table features a stable tripod base and a clean round tabletop, designed for weddings, events, hotels, cafés, and commercial venues.

Watch the installation video to see how easily this coffee table can be assembled on-site.

Reviews

There are no reviews yet.