Wooden Armchair Manufacturer

This wooden armchair embodies the perfect combination of minimalist aesthetics and Oriental charm, with its smooth lines and sculptural shape. The chair back features a one-piece bentwood design, presenting a unique, embracing arc that provides excellent support and adds a visual sense of art. The seat surface uses a soft woven cushion, which is comfortable to the touch and breathable, improving the overall sitting experience. The chair body is made of high-quality solid wood, with a natural and delicate texture and a stable and durable structure. Whether it is in high-end restaurants, private restaurants, family restaurants, cafes, hotel lounges, art exhibition halls, wedding banquets and other places, this chair can be perfectly integrated to create an elegant, comfortable and stylish space atmosphere.

Wooden Arm Dining Chair Feature

- Elegant design: The unique curved backrest has smooth lines and a strong sense of shape.

- Sturdy and durable: The structure is stable, the load-bearing capacity is strong, and it is suitable for long-term use.

- Comfortable sitting feeling: The seat surface is matched with hand-woven cushions, which are soft and breathable.

- Versatile and practical: It is suitable for a variety of places, including homes, restaurants, cafes, hotels, exhibition halls, weddings, etc., with a versatile style.

Description

-

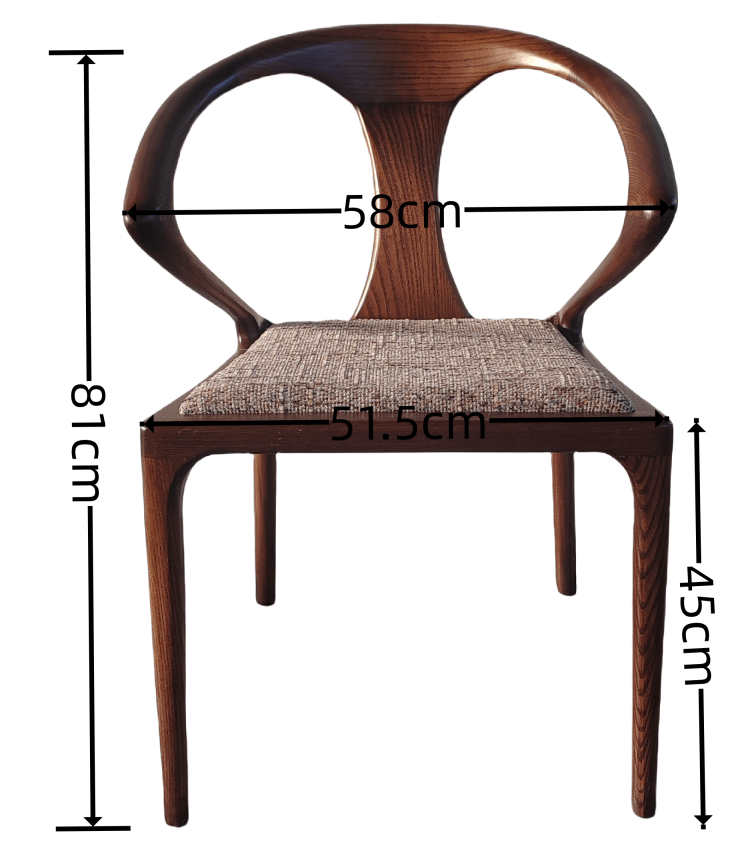

Wooden Armchair Dimension

-

Wood Selection and Preparation

The entire production process begins with the selection of wood. We use high-quality hardwood with natural

texture and tight structure (commonly oak, beech, etc.). Each batch of timber must be strictly inspected before

entering the production line to ensure that it is free from knots, cracks, and insects. Afterwards, the wood will

enter the high-temperature drying kiln, where the moisture content will be controlled between 8% and 12%

to prevent deformation and cracking during subsequent processing.

-

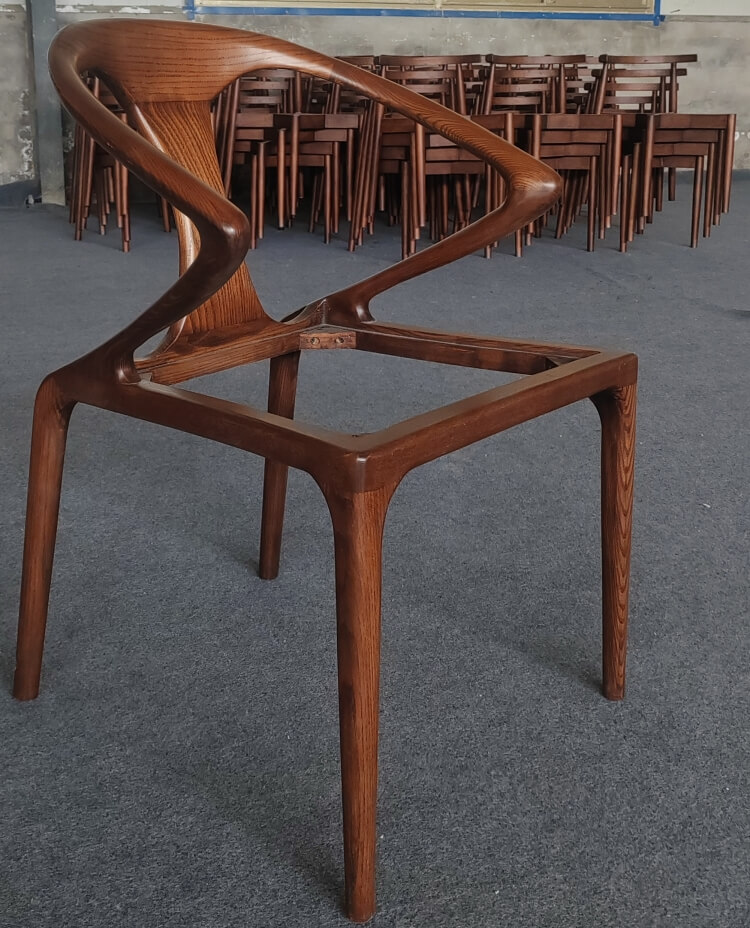

Chair frame moulding

After the wood is dried, it enters the CNC processing stage. A high-precision five-axis machining center is

used to cut and punch the chair legs, seat frame, chair back, armrests and other parts to ensure the uniform

connection accuracy between the parts. This chair has a unique shape, especially the integrated ring structure

of the armrest and backrest, which requires a difficult bending process. We use steam heating and then die

molding to ensure that the curve is natural and smooth and has sufficient strength.

-

Grinding and finishing

After all parts are processed, they enter the manual sanding process. Sanding is carried out in three rounds,

using coarse sand, medium sand and fine sand respectively, focusing on the joints, curves and edges to ensure

that every part is smooth and delicate. During the sanding process, workers need to ensure that the direction

of the wood grain is consistent to avoid sanding marks that damage the overall texture.

-

Assembly and structural reinforcement

The polished parts will be assembled and fixed with traditional mortise and tenon joints combined with

strong wood glue. Some key stress-bearing parts are reinforced with hidden hardware to improve the

stability and durability of the whole chair. After assembly, the whole chair is checked again for diagonal,

horizontal and vertical degrees to ensure that the chair frame is rigorous, not shaking or loose.

-

Cushion production and installation

The seat cushion is made of high-density rebound sponge, covered with breathable cotton and linen-blended

fabric, and hand-sewn by skilled craftsmen. Each cushion is cut according to the seat mold, with smooth edges

and even stitching, and is firmly installed in the chair frame through screws or slot structures to ensure a soft

and stable sitting feel.

-

Wooden Armchair Surface coating

After the whole wooden armchair is formed, it enters the painting process. We use environmentally friendly water-based

paint for three coatings: primer to close the pores, middle paint to strengthen the surface, and topcoat to give

natural lustre and protection. After spraying, it is naturally air-dried and dried at a constant temperature twice

to ensure that the paint surface is uniform, has strong adhesion, and is moisture-proof and stain-resistant.

Reviews

There are no reviews yet.