Wooden Buffet & Catering Table Wholesale

This buffet table is designed specifically for wedding receptions, banquets, and buffet settings. Its sturdy overall structure and flat, spacious tabletop provide ample space for food, beverages, and decorations. The modular design allows for efficient assembly and disassembly, facilitating quick setup and turnover. The table’s robust support system can withstand heavy loads, making it suitable for high-frequency use. It can also be used with tabletop racks to maximize space utilization and create a more organized buffet display, making it a practical choice for event venues and rental businesses.

Wooden Buffet & Catering Table Feature

- The reinforced table legs and sturdy connection structure ensure even weight distribution, making it suitable for frequent use and long-term handling.

- The modular design allows for easy and time-saving installation, facilitating quick setup and dismantling at event venues.

- The sturdy tabletop provides reliable support, allowing you to safely place various food items, drinks, and display items on it, ensuring greater peace of mind during use.

- Optional shelving designs are available to improve vertical space utilization, making the buffet display more neat and organized.

- Separate packaging design, supports customized cartons, saves container space, and is suitable for bulk transportation and warehousing management.

- Widely applicable to various commercial settings, including wedding receptions, banquets, buffets, and event rentals.

Description

Wooden Buffet Table Size

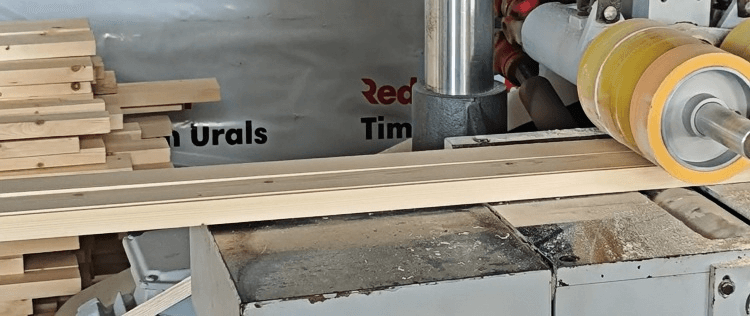

Selection and preliminary processing of raw materials

The production of buffet tables begins with strict control over raw materials. The main body of the table and

cabinets are made of high-quality panels with stable structure and uniform density, possessing excellent

load-bearing capacity and resistance to deformation, making them suitable for high-frequency use in banquets

and buffets. Before production, all panels undergo drying, leveling, and size calibration to effectively control

moisture content and reduce warping or cracking caused by environmental changes, thus laying the foundation

for overall structural stability.

The countertop is precisely cut according to the design specifications, and the edges are meticulously finished.

It then undergoes multiple polishing processes to create a smooth, even surface with a delicate feel. The

countertop has a substantial overall thickness and a stable structure, enhancing both its visual weight and

its durability and impact resistance during daily use.

Cabinet frame manufacturing

The cabinet frame is assembled from multiple panel components, each of which undergoes grooving, drilling,

and structural prefabrication during the manufacturing process. The frame structure emphasizes overall force

balance, and through a rational arrangement of columns and beams, the cabinet maintains excellent stability

even under full load, preventing wobbling and making it suitable for long-term display and use.

Critical stress points, such as the connections between uprights and beams, the weight-bearing areas of the

catering table tabletop, and the bottom support structure, are all reinforced to effectively enhance the overall

load-bearing capacity and deformation resistance of the catering table. The multi-point support structure

ensures that the cabinet remains stable, does not sag, and does not wobble even when fully loaded with

tableware or display items, meeting the demands of prolonged and frequent use in buffet and banquet settings.

Surface painting and coating curing process

After structural processing and assembly are complete, the product enters an automated painting production

line for surface coating. The painting process utilizes a closed-loop spraying system with evenly distributed spray

guns to ensure uniform paint coverage and consistent thickness. During the spraying process, the product

moves steadily along the conveyor system, minimizing human intervention and effectively preventing issues

such as sagging, color variations, or uneven coating.

After the painting process is complete, the components immediately enter a continuous drying and curing system.

Through precise control of temperature and time, the paint film quickly forms and adheres firmly to the surface.

This process not only improves the surface texture, making the colors more delicate and stable, but also enhances

the wear resistance and durability of the coating, meeting the dual requirements of appearance and quality for

buffet tables and banquet furniture in high-frequency use environments.

After the spray painting is completed, all components of the buffet table are placed in a designated drying

area and left to dry for the specified time. By controlling the spacing between the components and ensuring

proper ventilation, the paint surface is allowed to dry thoroughly and adhere firmly, preventing damage

caused by premature handling and further enhancing the overall appearance and durability.

After the paint surface is completely dry, the product enters the fine polishing stage. Workers meticulously

polish the surface, smoothing out minor imperfections and removing any granular texture, resulting in a flatter,

smoother surface with a delicate feel. This lays the foundation for subsequent processes and ensures a

high-quality appearance for the finished product.

Second Coat of Paint and Surface Finishing

After sanding, the product enters the second painting process. This step is primarily used to improve the

uniformity and color saturation of the paint finish, resulting in a more stable and consistent overall color.

After painting, the paint layer is fully cured again, making the surface texture finer and further enhancing its

wear resistance and stain resistance, meeting the requirements for use in banquet and buffet environments.

Overall Assembly and Detail Adjustment

The bottom of the buffet table is fitted with durable leveling feet, which distribute the load through multiple

support points, enhancing the stability of the cabinets even when fully loaded. The design of the leveling feet

effectively isolates the cabinets from ground moisture, reduces wear and tear, and extends the lifespan of the

cabinets in high-frequency use environments.

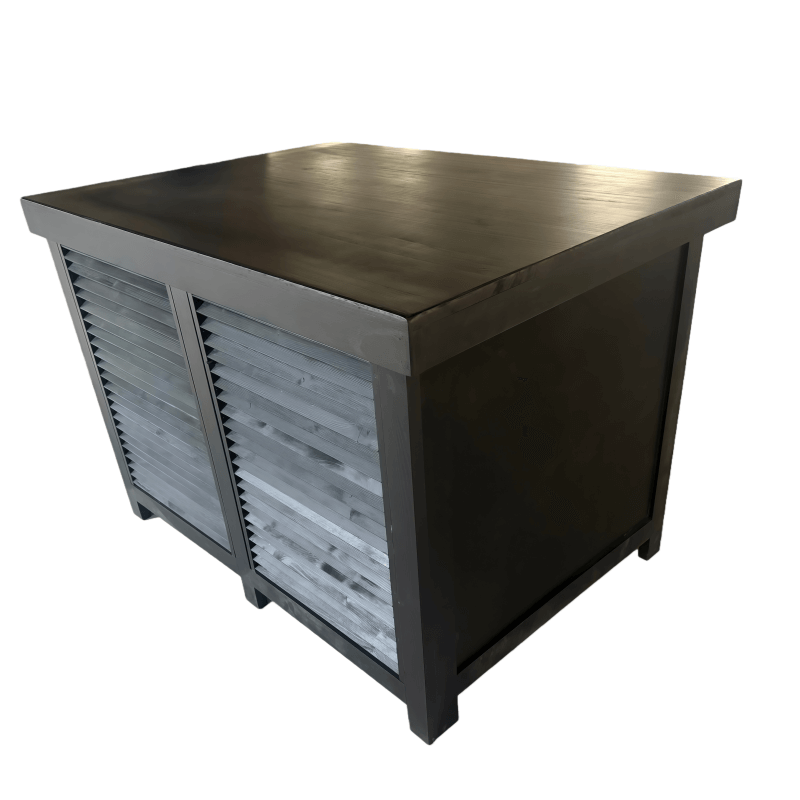

Louvered Door Panel Processing

The catering table doors feature a louvered design, consisting of multiple wooden slats evenly spaced and

fixed together. Each louver slat is individually sanded and polished, resulting in smooth edges and a neat

arrangement. This structure not only enhances the three-dimensional appearance of the cabinet but also

creates a visually light and natural feel, combining both decorative and practical functions.

Before assembly, all components undergo dimensional verification to ensure accuracy. During assembly,

multi-point fixing and reinforced connections are used to ensure a stable and reliable cabinet structure.

After the door panels are installed, they are repeatedly adjusted to ensure smooth opening and closing and

uniform gaps. The bottom support structure is reinforced to ensure even weight distribution across the

catering table, improving long-term stability and durability.

Our buffet tables are available in two standard colors: classic white and sophisticated black, easily blending

into various event settings. Whether for weddings, banquets, or buffet events, they exude elegance and style.

In addition, we support custom color options, allowing clients to personalize their choices based on the venue

theme or brand style. This ensures the tables are not only practical and durable but also perfectly complement

the overall environment. Whether using a single color or a mixed combination, our tables meet the decorative

needs of different settings and provide more creative possibilities for event design.

Buffet Table Stand

Our buffet tables are designed to be sturdy and durable, and they also feature optional tabletop shelves for

convenient placement of tableware, drinks, or decorations, making buffet setups neater and more organized.

Assembly is quick and easy, the tabletop is flat and stable, and the legs provide strong support, capable of

bearing heavy loads to ensure safe use. Whether for weddings, banquets, or buffet events, this table, especially

when used with the optional shelves, enhances the overall presentation while providing greater flexibility and

convenience to meet the needs of various occasions.

Want to learn how to install the buffet table stand?

👉Please click here for detailed instructions.

Final Quality Inspection and Functional Testing

Before shipment, every finished product undergoes a rigorous final quality inspection. This inspection includes

checking the structural stability of the cabinet, testing the flatness of the countertop, verifying the smooth

operation of cabinet doors and drawers, and inspecting the overall appearance and paint finish. Only when

all indicators meet the standards can the product proceed to the packaging stage, ensuring consistent and

reliable quality upon delivery.

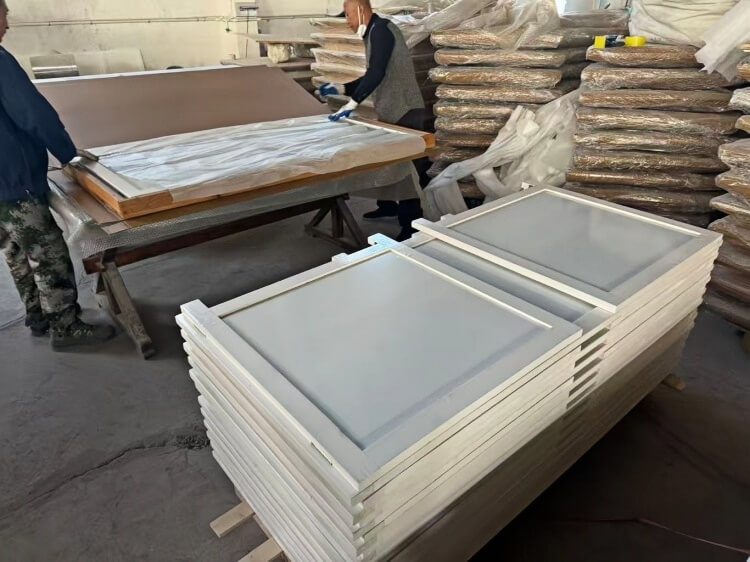

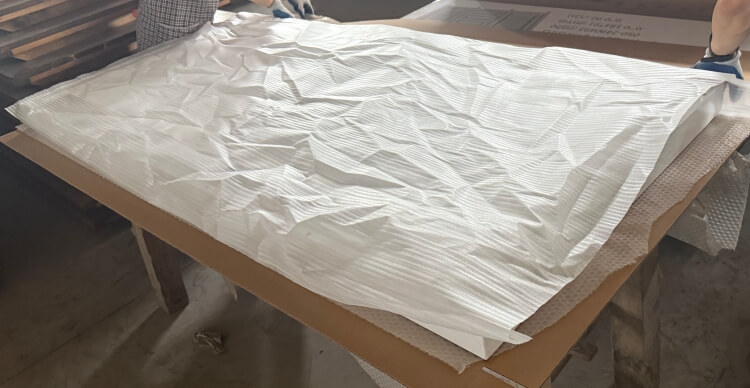

Efficient Packaging for Transport & Storage

The buffet table features a modular packaging design, with the tabletop and legs packaged separately for

easy handling and storage. Each component is protected with shock-absorbing pearl cotton, soft corner

protectors, and foam to prevent scratches, bumps, or damage during transportation. All screws and small

accessories are individually bagged to ensure nothing is missing. The compact and efficient packaging

not only improves container loading efficiency but also facilitates bulk shipping and long-term storage,

ensuring the table arrives safely and in perfect condition to the customer.

The products are then uniformly placed into specially designed cardboard boxes for packaging. The box

dimensions precisely match the product structure, ensuring a sturdy and pressure-resistant design. This

enhances transportation safety and facilitates container loading and stacking, guaranteeing that the products

remain in perfect condition during long-distance transportation and multiple transfers.

After packaging, the buffet tables are uniformly placed into custom-made cardboard boxes for protection.

During container loading, the boxes are arranged according to their size and product structure, neatly stacked

inside the container. Reinforcement and protection are added between layers to ensure overall stability.

Through tight arrangement and scientific loading, the risk of shaking and crushing during transportation is

effectively reduced, improving loading efficiency and maximizing the safety and integrity of the products

during long-distance transport.

Ideal Buffet Table for Weddings, Banquets & Events

Looking for more options?

Discover our full range of buffet tables designed for events and banquets.

🔗 Click here to see all styles

Want to learn more about our production process?

📌Watch our production video.

Reviews

There are no reviews yet.