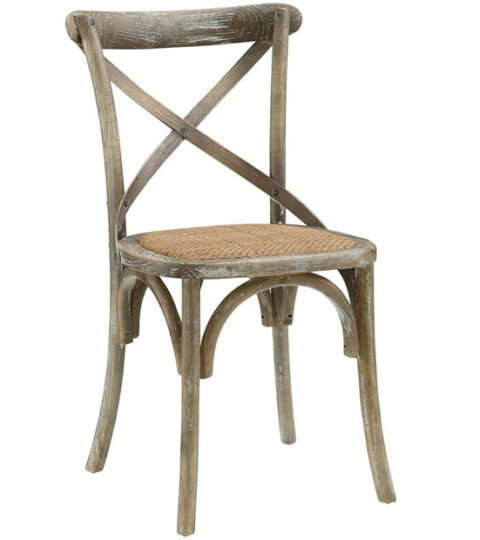

Resin Cane Dining Chair Factory

This resin rattan dining chair combines classic rattan design with modern durable materials. It is made of high-quality resin, light and convenient, and has excellent weather resistance and stability. The back and seat of the chair are made of imitation rattan texture and finely woven by hand, which not only retains the natural beauty of traditional rattan but also is more durable and not easy to wear or break. The curved backrest is ergonomically designed, providing good support and a comfortable sitting experience. Its waterproof, moisture-proof and UV-proof properties make it suitable for wedding banquets, restaurants, cafes, outdoor gardens and other occasions. It is not only beautiful and easy to clean and maintain, but also an ideal chair choice that combines elegance and practicality.

Resin Cane Dining Chair Feature

- High-quality resin material: The entire chair is made of high-quality resin. Compared with traditional wooden chairs, it is more weather-resistant, moisture-proof, and corrosion-resistant, not easy to crack or deform, and is suitable for various environments.

- Imitation rattan hand-woven design: The chair back and seat are made of imitation rattan texture and hand-woven, which gives it the natural beauty of rattan weaving. At the same time, it is more sturdy and durable and not easy to wear or break.

- Lightweight and easy to maintain: The resin material is lightweight and portable. Compared with traditional wooden rattan chairs, it is easier to clean and can be kept tidy with a simple wipe.

- Strong weather resistance: It is waterproof and UV-resistant, suitable for indoor and outdoor use, and is not easy to fade or age even if exposed to sunlight or humid environments for a long time.

Description

Everything starts with design. First, we will make a precise 3D design based on the shape, size and functional

requirements of the chair. After the design is completed, the technical team will make precise moulds.

These moulds are the key to the production of resin chairs and can ensure the consistency and accuracy of

each product.

The frame of the resin chair is made of high-quality resin material, which usually has excellent weather

resistance, UV resistance and waterproof performance. Injection moulding is the core step of production.

The resin melted at high temperature is injected into the mold to form the various components of the chair

under pressure. Each component needs to undergo strict cooling and shaping to ensure that its appearance

and strength meet the standards.

Once the resin parts are removed from the mould, they go through a deburring and trimming process. This

step ensures that every detail of the chair is smooth and flawless, without any sharp edges that would affect

the user experience. In addition, each part is quality inspected to ensure there are no bubbles, cracks or other

defects.

The uniqueness of the resin chair lies in its rattan-woven seat. The hand-woven process requires the

craftsmen to have extremely high skills and patience. They weave the selected rattan material tightly

according to the design requirements, making it have both a natural appearance and strong durability.

Each rattan needs to be woven evenly and tightly to ensure the comfort and beauty of the chair.

After assembly, each chair is thoroughly cleaned to remove dust and impurities generated during the

production process. The chair is then carefully packaged to ensure that it is not damaged during transportation.

The packaging material is generally environmentally friendly foam or cardboard, which has shock and

pressure-proof functions to ensure that the chair is safe and intact during transportation.

Reviews

There are no reviews yet.